high quality exothermic welding mold

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, Money Gram |

| Supply Ability: | 300/day |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Shaoxing, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Other |

Product Detail

| Model No.: | ZKEW |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| brand name: | ZKER |

| material: | graphite |

| Usage: | grounding system |

| Condition: | 100% Original |

| name: | exothermic welding |

| Production Capacity: | 300/day |

| Packing: | Carton-Pallet---Container or customer's requirement |

| Delivery Date: | lead time10-30days |

Product Description

Product Description:

1.Good current loading ability

the welding point current loading ability is the same as conductor.

2.Good mechanical performance

The connection is a molecular connection.It is a permanent connection.

3.Stable dash current resistance

The test shows that in the surge of big current in short time,the conductor melts earlier than the connection point,so it will not be damaged by surge current.

4.Good resistance to corrosion

The welding point is covered by copper,it provides good corrosion resistance .

5.Simple and safe connection

Neither extra power nor facility is required. lt requires very little time to finish one welding. lt can be done both indoor and outdoor.

6.Free control of the reaction temperature

Different welding powder is provided according to the metal features,so the welding joint can be very solid.

7.Range of application

It is widely used in lightning protection and grounding and surge protection projects, equipment grounding, petrochemical projects,airport and expressway construction.

Product Details Show:

high quality and performance exothermic welding mold

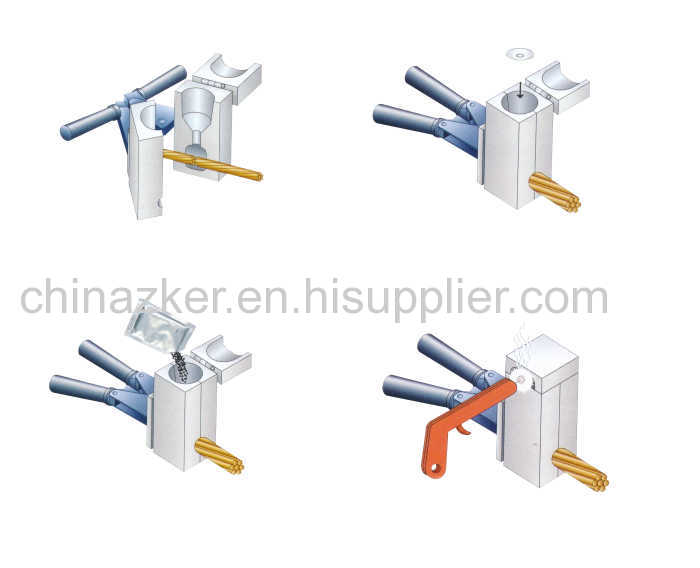

Making an connection:

Step1 Clean all conductors with a brush and then place the conductors into position in the open mold.Be sure to pre-heat mold prior to use.

Step2 Close the handle clamp to lock the mold into place.Place the disk into position in the mold ensuring it is correctly seated and covering the tap hole.

Step3 Place the welding powder into the crucible and position the starting powder on the lip of the mold in preparation for ignition.

Step4 Close the cover and ignite starting powder with flint gun.Open the mold after the metal solidifies.Remove the slag from the mold before making the next connection.

Note:

Be sure to pre-heat mould prior to use

Clean all conductors before welding

Put conductors in good position before lock the mould by handle clamp

Do not stand in front of the crater with 1 meter

Clean the mould after welding for the next connection

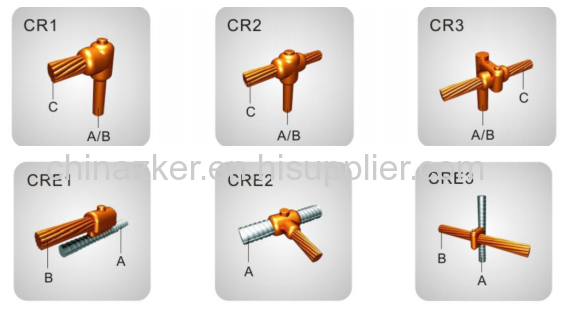

Exothermic Welding Joint

Our Company:

Enterprise Qualification:

Exhibition:

FAQ:

1.Are you a manufacturer?

We are exothermic welding mold manufacturers in China.

we have export license and can do export directly.

2. What 's your product ranges?

We supply lightning protection products and grounding products.

For instance, lightning rod, surge protection, ground rod, ground rod accessories, exothermic welding materials.

3. Can you engrave our mark on rod?

Yes, we can.

4. Can you produce according to our requests?

Sure as long as you offer detailed requests.

5. Do you provide samples ? is it free or extra ?

sorry, sample and freight cost should be at customer,because of the high cost.

6.What's your delivery time?

Usually we can finish one container in 25 days.

For normal size products, delivery time can be shorter.

And for regular orders, we can finish one container in one week.

7. What's your terms of payment?

Usually LC, TT

If you have another question, pls feel free to contact us

If you have another question, pls feel free to contact us