Isostatic Graphite Mold Exothermic Welding Isostatic Graphite Mold

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 99999999 |

| Place of Origin: | Jiangxi |

Company Profile

| Location: | Yichun, Jiangxi, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | NX605 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | ningheda |

| name: | Exothermic Welding Graphite Mold |

| material: | Isostatic Graphite |

| Production Capacity: | 99999999 |

| Packing: | Export grade wooden box |

| Delivery Date: | Agreement |

Product Description

Isostatic graphite mold, exothermic welding isostatic graphite mold

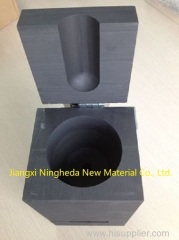

In general, exothermic welding isostatic graphite molds are used at high temperatures. This process is carried out at a high temperature of thousands of degrees. At this high temperature, ordinary metals such as iron, aluminum, and copper have long evaporated to the ash. , But the melting point of graphite is 3850 degrees, it is a very high temperature resistant material, so it is an ideal material for making exothermic welding molds.

The exothermic welding graphite mold of Jiangxi Ningheda New Material Co., Ltd. is made of high-quality and high-purity graphite. The graphite is of high quality, so the exothermic welding effect of the mold is particularly good, and it is very durable. A set of molds uses several Months later, the effect is still as new, so the exothermic welding graphite mold produced by Henan Liugong has been recognized by many domestic and foreign manufacturers and has been widely used.

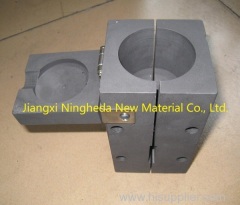

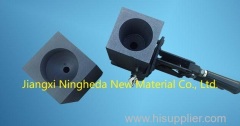

The graphite mold used for welding is composed of several parts, including mold cavity, mold cavity, injection hole and so on. This mold has connections of different shapes, such as straight-through, T-shaped, cross-shaped, and so on. The shape and size of the mold cavity and the flow direction of the molten metal are all carefully designed and manufactured, and the finished connector has a beautiful and consistent appearance.

The service life of the graphite mold is 50 times skilled, and the operator can make the mold life to 100 times. The mold is made of graphite, is small in size, and weighs only 0.5 to 1 kg, which is convenient to carry. The fixture of the mold is used to fix the mold.

Exothermic welding must be done using a specially manufactured mold. This casting mold (welding mold) is made of high temperature resistant graphite. This kind of mold can withstand the high temperature when the metal melts.

Technical Characteristic: