Accessen all welded bloc heat exchanger

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 3000SET/MONTH |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Accessen PHE |

|---|---|

| Means of Transport: | Ocean, Air, Land |

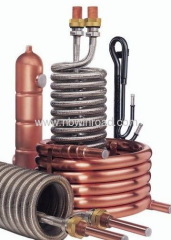

| Category: | Heat Exchanger |

| Capacity Type: | Medium Duty |

| Certification: | CE |

| Brand Name: | ACCESSEN |

| TYPE: | PLATE HEAT EXCHANGER |

| Production Capacity: | 3000SET/MONTH |

| Packing: | STANDARD EXPORT PACKAGE |

| Delivery Date: | 30DAYS AFTER PAYMENT RECEIVED |

Product Description

All Welded Bloc Heat Exchanger is probably the most compact and efficient heavy-duty heat exchanger in the world.

All welded bloc heat exchanger is a breakthrough plate heat exchanger that combines a whole range of technological advantages into one compact unit. The all-welded plate pack does away with all gaskets between plates, and makes it possible to operate with a wide range of aggressive media and at high temperatures and pressures.

Corrugated plate patterns generate high turbulence that results in overall heat transfer coefficients three to five times greater than a shell-and-tube heat exchanger. In addition to minimizing fouling, this makes it financially viable to use corrosion-resistant exotic metals.

This makes this fully welded graphite bloc heat exchanger perfect for heat recovery in corrosive operating environments and for handling aggressive, high-temperature fluids of all kinds. The compactness of this all-welded bloc heat exchanger means it can be installed virtually anywhere - as a condenser or reboiler for distillation and stripping columns, as a condenser on top of reactors and in a wide range of other heat exchanger applications.

Accessen fully welded graphite bloc heat exchanger is available in various corrugation designs and sizes for a wide range of applications. Adjustable deflectors allow the heat exchanger to be adapted to its operating points delivering these features:

1. Max. operating temperature 315°C, on both sides

2. Max. operating pressure 32 bars, on both sides

3. Material 1.4404, SMO, Titanium, etc.

4. Surface area 1-320m²

5. Connection diameter DN50-DN400

6. Max. flow rate 3,860m³/h

7. Corrugation patterns: Herring-bone, Dimple

This all welded bloc heat exchanger is generally used in industries like oil and gas, petrochemicals and chemicals, automobile and pharmaceuticals, as well as paper manufacturing