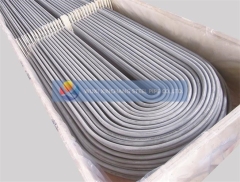

Heat Exchanger Welded Steel Tube

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

Name | Heat Exchanger Welded Steel Tube |

Standard | ASTM A778,ASTM A312 |

Material Grade | 304,316,316L,430 |

Main Material | a) 304 (Ni: 8% Cr: 18%) b) 316 (Ni: 10% Cr: 18%) |

Outer Diameter | 12.7mm-3000mm |

Thickness | 0.5mm - 50mm; SCH10/40/80/160/XXS/STD |

Length | 6m or as customers' request |

Tolerance | a) Outer Diameter: +/- 0.2mm |

b) Thickness: +/- 0.02mm | |

c) Length: +/- 5mm | |

Surface | 180G, 320G Satin/Hairline 400G, Mirror finish |

Heat Exchanger Welded Steel Tube Physical properties

Property | Value |

Density: kg/dm3 | 7,9 |

Hardness: HB | 130-190 |

Hardness HB 30 | <=215 |

magnetizable | no (might increase due to cold deformation) |

Temperature T | Specific heat | Thermal conductivity | Electric resistance | Modulus of elasticity | Expansion rate from 70°F bis T |

20 / 68 | 500 (-) | 15 (-) | 0,73 (-) | 200 (-) | 16,0 (-) |

200 /392 | 186 (-) | 16,5 (-) | |||

300 / 572 | 179 (-) | 17,0 (-) | |||

400 / 752 | 172 (-) | 17,5 (-) | |||

500 / 932 | 165 (-) | 18,0 (-) |

temperature | 0,2%Yield strength | 1,0% Yield strength |

°C / °F | Rp 0,2 | Rp 1,0 |

N/mm2 /ksi | N/mm2 /ksi | |

100 / 212 | 176 / 25,50 | 208 / 30,16 |

200 / 392 | 157 / 22,77 | 186 / 30,00 |

300 / 572 | 136 / 19,70 | 167 / 24,20 |

400 / 752 | 125 / 18,10 | 156 / 22,60 |

500 / 932 | 119 / 17,00 | 149 / 21,60 |

ksi value calculated | ||

Mechanical properties (20°C / 68°F)

1% Yield strength Rp1,0 (Mpa / ksi) | 240 / 34,8 |

Tensile strength Rm (Mpa/ksi) | 500-700 |

Elongation A5 (%) | 40 |

impact work ISO-V | 60 J |

Temparature information

Application area | |

Operation temperature | ºF to 1652 ºF |

Explanation report | air |

Solution heat treatment | |

Working temperature | 1886 ºF to 2030 ºF |

Processing informations | cool down: water;air |

Annealing | |

Working temperature | 1832 ºF to 2012 ºF |

Explanation report | duration 5 min; width 5 mm |

Processing informations | cool down: water;air |

Solution heat treatment | |

Working temperature | 2102 ºF to 1562 ºF |

Processing informations | cool down: air |

Standards / information

Standards | Desciption |

ASTM A 249 | Standard Specification for Welded austenitic steel boiler, Superheaters, heat-exchangers,and condenser Tubes |

ASTM A 269 | Standard Specification for Seamless and welded, austenic, and stainless steel tubing for general purposes |

ASTM A 312 | Standard Specification for Seamless and welded austenitic stainless steel pipes |

DIN EN 10217-7 | Welded steel pipes under compression load Pipes made from stainless steel |

DIN EN 10296-2 (02/2006) | Welded circular steel pipes for machine construction and general technical service stainless steel |

DIN EN 10297-2 (02/2006) | Welded circular steel pipes for machine construction and general technical service stainless steel. Pipes made from stainless steel |