.jpg)

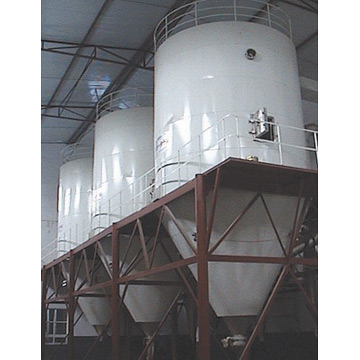

Spray Dryer

| Min. Order: | 1 unit |

|---|---|

| Payment Terms: | TT / LC |

| Supply Ability: | 1UNIT |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | By sea |

|---|---|

| Brand Name: | Ruipai |

| Specification: | 0.5T/H-5T/H |

| Patent Rights: | Ruipai |

| Certificate: | CE , HACCP, ISO9001 |

| Export Area: | all over the world |

| Production Capacity: | 1UNIT |

| Packing: | WOODEN CASE |

| Delivery Date: | 30DAYS |

Product Description

Equipment classification

.

According to the flow direction of hot air and materials: co-current flow type, counter-flow type, and mixed flow type.

According to the way of air discharge: up air discharge, quarter air discharge, and bottom air discharge.

Structure feature

·According to the performance of material ,we can design several branches of cyclones and powder collector of matching grade, and we can also design powder collector of hop-pocket type, and the multi-level cyclone powder collector has increased the efficiency of collecting powder. The hop-pocket adopts pulse anti-absorbing system and new hop-pocket materials, so it can avoids fluctuation in the tower, and is easy to clean.

·The vibrating fluid bed adopts the advanced technology from home and abroad, and it would achieve the desired goal of secondary drying., at the same time, it reduces the temperature of the materials, energy consumption and products to guarantee the products quality.

The inlet air exhauster is equipped with wind regulating door, and is controlled by the transducer, so it is easy to startup the machine without material and adjust pressure of the tower

We can install anti-burst device and self-control system as per customer's requirement

We can add inner fluid bed as customer's requirement ,which would achieve secondary pelleting.

Flow of the pressure spray drying (quarter air discharge)

Features

Second-grade drying, one-stage and double cyclones or double-stages and four cyclones or two- stages cyclones , quarter symmetry air discharge, wind, fine powder agglomeration, CIP cleaning system

Flow of the pressure spray drying(up air discharge)

Features

·third –stages drying, one-stage and double cyclones, two-stage cyclone or double-class four cyclone for collecting powder, ,up air discharge, fine powder agglomeration, CIP cleaning system.

Flow of the pressure spray drying(down air discharge or bottom air diacharge)

Features

·two-stage drying, single-stage and double cyclones ,two-stages cyclones or two stage four cyclones, up air discharge, fine powder agglomeration, CIP cleaning system.

Flow of centrifugal spray drying

Features

two-stage drying, single cyclone or two- stage and(four cyclones) for collecting powder, down air discharge or quarter collecting powder, CIP cleaning system.