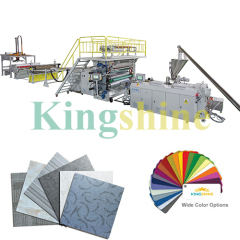

EPE Foam Packing Sheet Production Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100Set/Year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Yantai, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | FS-FPM90 |

|---|---|

| Means of Transport: | Ocean, Land |

| Material: | PE |

| Product: | Foam sheet |

| Gas injection: | Butane pump |

| Density: | 20-30 kg/M3 |

| Type: | Long single |

| Screw L/D: | 55:1 |

| Cooling: | by wind or water |

| Weight: | 7.5-17MT |

| Certification: | CE |

| Delivery time: | About 45days |

| Production Capacity: | 100Set/Year |

| Packing: | Export standard packing |

| Delivery Date: | About 45days |

Product Description

What is the features of our The latest EPE foam sheet extrusion machine ?

1.Damping,Resist static electricity,Dust-proof 2.packaging material:electronic equipment,pottery,glass products,furniture 3.insulation material:Agriculture,building |

What is description of our The latest EPE foam sheet extrusion machine ?

| PE foam sheet extruder producing fine closed cell Polyethylene foam sheet, by our unique designed Screw and Barrel system, using Butane foaming agent, Talc powder or Talc master batch and Anti-shrinking agent (GMS for short-Surface Active Agent) by accumulated experience and advanced technology. |

1. PE foam and related products are made from PE resin and it is expanded and formed into sh apes by being heated and extruded. And it is easy to be decompounded and environment frien dly. |

| 2. Its key function is cushion protecting and warmth reserving. |

3. Nowadays it is the most popularly used for modern batch production products; especially ex port packaging industry, including electronic industry (such as PC computer, laptop, and electr onic chips and parts, inverter, TV, air conditioner, refrigerator), furniture, glassware, garment s, metal parts,etc |

4. Whoever aims at modern packaging and export, he has to use PE foam for the following rea sons:Packaging with air bubble film, EPS and plastic film is forbidden in many countries. Pap er packaging is so expensive. |

5. PE have few varieties: Sheets for direct wrapping and to make bags; PE sheet may be coate d with plastic film, craft paper and aluminum foil. It may be laminated (by electricity or LPG f lame) into thick blocks. Then cut them to make different containers or frames. PE fruit net is d irect for fruit and small matter's wrapping. If you add special molds, you may make different p rofiles for door hinges and furniture packing. |

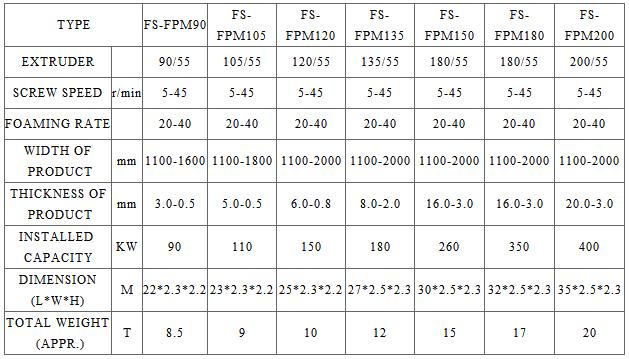

SPECIFICATION

THE LATEST EPE FOAM SHEET EXTRUSION MACHINE :

The latest EPE foam sheet extrusion machine Why choose us?

STEEL RACK STRUCTUR

| Rack material | carbon structural steel, standard steel section |

| Water recycling system | stainless steel connection |

TALCUM POWDER INJECTION UNIT (ITALY TECHNOLOGY)

| Feeding capacity | 0-1.5 kg/h |

| Feeding method | sprial and constantly |

| Driving motor | 0.25KW×2 |

Talcum powder injection unit adopts Italy technology. Double screw substitute single screw, S olve the poor mobility features of talcum powder. The motor is controlled by inverter to mak e talcum powder injection accurate and stable |

AUTO NET CHANGING SYSTEM

| Hydraulic station | 1 set |

| Motor power | 2.2 KW |

| Heating area | 3 pcs |

AIR RING & SHAPING DRUM UNITunit

| Air ring | |

| Material | Aluminum |

| Blowing method | air blower |

| Shaping drum | |

| Material | steel |

| Cooling method | wind cooling |

| Methods for cutting open | round cutter motor driven |

| Shaping drum size | customer product decided |

| Air blower | 1.5KW |

HAUL-OFF UNIT

Material | STPG tube hard chrome plating |

Driving motor(adjustable) | 1.5KW/4P×2 |

Material of expanding roller | stainless steel |

Press roller | rubber, driven by cylinder. |

Static electricity eliminator | ion fan |

Length control | controlled by meter counter, could pre-set, equipped with the length alarm |

WINDING UNIT

| Model | Double axis cantilever displacement type(air shaft type) |

| Maximum of rolling weight | Maximum 20kg×1m(diameter) |

| Driving motor regulative | Torque motor 16N.M×2 sets |

| Revolving driving motor | 0.75KW×1/10 Turbine vortex stem reducer system |

SUCCESSFUL ORDERS

COMPANY VIEW

MACHINE EXPORT

CONNECT INFORMATION