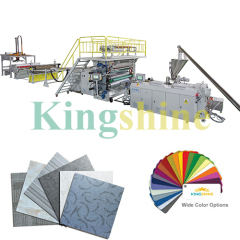

PVC Laminating Sheet Production Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | SZ80/156 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | KINGSHINE |

| Plastic type: | PVC |

| Brand name: | Kingshine |

| Product width: | 1220mm |

| Product thickness: | 0.8~2mm |

| Capacity: | 400kg/h |

| Motor: | 75kw |

| Export port: | Shanghai |

| Warranty: | 1 year |

| Production Capacity: | 20 |

| Packing: | wooden case or FCL |

| Delivery Date: | 45days |

Product Description

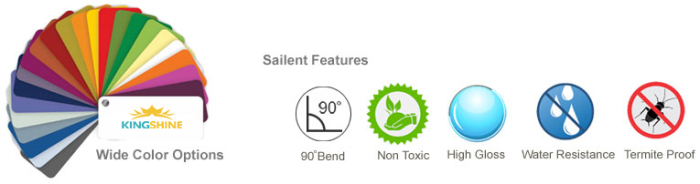

PVC laminating sheet advantages

1.PVC Laminate saves the time of the contractors as the same sheet is used for packing the side. There is no need to use edge bands. PVC laminate can be folded upto 90 degrees which makes it stand out among other options.

2.These laminates are safe for kitchen as they are corrosion resistant, termite resistant, borer resistant, stain resistant, water resistant, lead free, environment friendly, harmful emission free, easy to clean and toxin free.

3.A PVC laminate can be easily cleaned without worrying about the finish as they are waterproof.

4.This sheet comes in many colors and texture and also highly durable.

5.The installation of PVC laminate is very easy and is done without any tension

6.One of the attractive features of PVC laminates is that they are economical. You get the look and feel of luxurious items at very reasonable rates.

7.PVC laminates are pre finished, which means there is no need of giving finish before application.

Production Line Processing

Raw material→ Mixer→ Extrusion→moulds→3-roller calendar→ hauling off→ cutting device→ stacking device→ checking up→ packing

With PVC sheet production line, PVC sheet is extruded out and shaped by three-roll calender. And the sheet surface is treated with lamination directly in line, which makes the sheet in many colors and texture. Kingshine PVC extruder adopts European standard. All part is controlled by Siemens PLC.

Technical parameter

| Model | 80-156 | 92/188 |

| Thickness(mm) | 0.8-8 | 0.8-8 |

| Width(mm) | 1350 | 1350 |

| Extruder Motor(kw) | 75 | 110 |

| Max Capacity(kg/h) | 450 | 750 |

Kingshine supply PVC laminating sheet extrusion line not only machine but also formula and technology, help customer start the project with professional service.

About Us

Jiangsu Kingshine Plast Machine Co.,Ltd is one of the most professional plastic machinery manufacturing enterprises in China. The main production is SPC/LVT floor extrusion machine, PVC sheet extrusion machine, PVC/WPC door board/frame extrusion machine, PVC laminating/marble sheet extrusion machine, ect. Kingshine pay attention to technological innovation, actively introduce advanced foreign technology, and constantly develop new products.

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Contact:

Joy Zhang

Int'l Sales Manager

Mobile/Whatsapp: +86 13405773767

Skype/Wechat: yizhang28