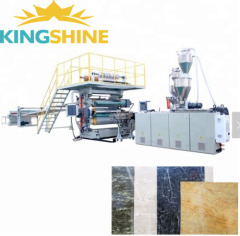

PVC Marble Strip Production Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 0-200sets per year |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | KPM |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | BENK |

| main extruder: | SJZ65/132 conical double screw extruder |

| output: | MAX 250KG |

| profile size: | MAX 300*60mm |

| main motor: | 37KW SIEMENS motor |

| inverter: | ABB |

| hot stamping machine: | 10sets |

| installation size: | 34*2*3M |

| installation power: | 98KW |

| machine color: | according to your idea |

| certificate: | CE ISO9001 |

| Production Capacity: | 0-200sets per year |

| Packing: | suitable sea transport package |

| Delivery Date: | 35 working days after deposit money received |

Product Description

PVC Marble Strip Production Line

Features of the marble profiles:

1. Green environmental protection, also recyclable.

2. PVC super wear-resistant floor surface has a layer of special by high-tech processing transparent wear-resistant layer, withwear resistance strong, so PVC floor more and more popular in the hospital,in school, office buildings, shopping malls,supermarkets, transportation and other places.

3. Safety, insulation, flame retardant, corrosion resistance, alkali resistance, 5% acetic .5% hydrochloric, no abnormal surface. Leave the flamefor five seconds and can self extinguish.

4. Novel color, a variety of colors available for selection, brilliant color,natural and vivid color, any spell group shape, highlight the individuality color.

5. Installation convenience,convenient construction sawing, planing, nail, glue free paint.

6. Long service life can reach more than 20 years.

Usage:

1. Used as background wall frame for the TV, sofa, etc.;

2. Used as the door frame for great decorative effect, etc.;

3. Used as the decorative ceiling corner, etc.;

4. Used for the hotel, restaurant, living room and many other places;

5. Door frame moulding, edge banding, press line, skirting, borders, Vertex angle line, pull through plate, ect.

machine list and qantity:

PVC raw materials Mixing system | |

1. Spiral Loader or Vacuum auto Loader | 1 set |

2. High speed Heating Cooling Mixer unit | 1 set |

PVC Moulding Profiles Extrusion Line | |

1. Spring Loader | 1 set |

2. SJZ65/132 Conical double screw Extruder SJ45/25 single screw extruder(surface co-extrusion) | 1 set |

3. Mold/Die head Set | 1 set |

4. Vacuum calibration Table | 1 set |

5. Thermal stamping | Multiple sets |

6. Haul off unit | 1 set |

7. Cutting unit | 1 set |

8. Stacker | 1 set |

Profiles Recycling machines | |

1. Sheet/Plate hard Crusher/Grinder | 1 set |

2. PVC Pulverizer/Miller | 1 set |

Reference pics from client's factory:

finsihed profile & its function:

setting way: use glue connect with wall

Main technical parameter:

| main extruder | SJZ65/132 conical double screw extruder |

| surface co-extrusion | SJ45/25 single screw extruder |

| output | 250KG/H MAX |

| main motor | 37KW SIEMENS motor |

| inverter | 37KW ABB inverter |

| instalaltion power | 98KW |

| installation size | 34*2*3M |

| hot stamping machine | 10sets |