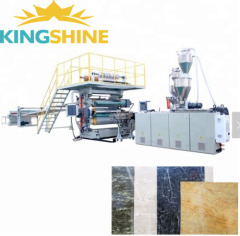

PVC Marble Sheet Production Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 20 sets per month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | kpm |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | BENK |

| board wide: | 1220mm |

| thickness: | 1-8mm usually |

| extruder: | SJZ80/156 |

| main extruder: | 75KW |

| output:: | 350KG |

| motor: | SIEMENS motor |

| inverter: | ABB |

| installation size: | 22X4X3.5M |

| color: | according to you idae |

| certificate: | ISO9001 CE |

| Production Capacity: | 20 sets per month |

| Packing: | suitable sea transport package |

| Delivery Date: | 40 working days after deposit money received |

Product Description

PVC Marble Sheet Production Line

1. Advantage of PVC Marble Sheet Production Line:

Bi-Metal Screw and Barel guarantee the extruder running time more long.

Using Inverter, it will help save large quantity power

PLC control, making the machine running full automatic, less labor need.

Surface Co-extrusion PVC layer, making it more stronger used for Construction.

High percentage calcum carbonated foumula, save cost of raw material for client

Marbe sheet used widely four building decorating, like hotel, resturant, personal house, KTV etc.

surface UV cotaing making the board looks more beautiful and hard.

SJZ80/156 conical double screw extruder for PVC Imitation Marble Production Line

2, reference pictures for PVC Marble Sheet Production Line

2. Three roller Calender for PVC Imitation Marble Production Line

3. Lamination device for PVC Marble Sheet Production Line

PVC marble sheet function:

3. PVC Marble Sheet Production Line Main technical parameters:

No | Item | parameter |

1 | thickness | 1-8mm |

2 | size | 2.44*1.22m |

3 | weight | 20-25kg/piece |

4 | output | 1200-1350 Square Meters(24h) |

Want more information for BENK's PVC Imitation Marble Production Line, plesae feel free contact us!