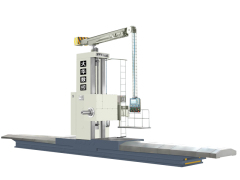

Floor Type Boring and Milling Machine

200000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 sets/month |

| Place of Origin: | Liaoning |

Company Profile

| Location: | Dalian, Liaoning, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Tk Series |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Cnc |

| Raw Material: | Others |

| Machine Type: | Others |

| Extra Services: | Machining |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Haisen |

| Production Capacity: | 20 sets/month |

| Packing: | seaworthy packing |

| Delivery Date: | 3 month |

Product Description

Product description:

The CNC boring and milling machine is based on modularized CNC machine, ad hoc suitable for producing a group of holes in a very long, large or heavy part. The machining range can be broadened by adopting right-angle milling heads, universal milling heads and CNC rotary tables, to accomplish accurate machining of complex and heavy parts.

Specifications:

| Parameters | Unit | TK6211 | TK6213 | TK6216 | TK6913 | TK6916 |

| Spindle diameter | mm | 110 | 130 | 160 | 130 | 160 |

| Spindle tapered bore | ISO 7:24 No50 | ISO 7:24 No50 | ISO 7:24 No50 | ISO 7:24 No50 | ISO 7:24 No50 | |

| Milling shaft diameter | 221.44 | 260 | 221.4 | 260 | ||

| Spindle speed | r/min | 10-2000 | 10-2000 | 10-1500 | 10-1500 | 10-1000 |

| Max. spindle torque | N.m | 1300 | 2800 | 3500 | 2500 | 3000 |

| Cross section area of ram | mm | 480*480 | 480*480 | |||

| Travel of column(side base)X | mm | 4000 (per 1000 increasing) | 4000 (per 1000 increasing) | 4000 (per 1000 increasing) | 4000 (per 100 increasing) | 4000 (per 1000 increasing) |

| Vertical travel of spindle box(carriage)Y | mm | 1500 | 1600 | 2000(2500) | 2000(2500,3000) | 2000(2500,3000) |

| Travel of ram Z | mm | 700 | 700 | |||

| Travel of spindle W | mm | 550 | 800 | 1000 | 700 | 700 |

| Main motor power | Kw | 17/22.5 | 37/51 | 37/51 | 37/51 | 37/51 |

| Cutting feed speed X,Y,Z | mm/min | X,Y:1-6000 | X,Y:1-6000 | X,Y:1-6000 | X,Y:1-6000 | X,Y:1-6000 |

| A,B | r/min | W:1-2000 | W:1-3000 | W:1-3000 | W:1-3000 | W:1-3000 |

| Rapid moving speed | m/min | X,Y:9 W:2.4 | X,Y:8 W:3 | X,Y:9 W:3 | X,Y:6 Z,W:3 | X,Y:6 ZW:3 |

| Tool magazine capacity | 40 | 40 | 40 | 40 | ||

| Tool shank specification | ISO 7:24 JT50 | ISO 7:24 JT50 | ISO 7:24 JT50 | ISO 7:24 JT50 | ISO 7:24 JT50 | |

| Blind rivets standard | LD50D | LD50D | LD50D | LD50D | LD50D | |

| Positioning accuracy X,Y,Z,W | mm | X:0.22 Y,W:0.02 | X:0.035/100 Y:0.020 W:0.02 | X:0.032/1000 Y:0.026 W:0.02 | X,Y:0.026/1000 Z,W:0.03/ overall length | Y,Z,W:0.026 |

| Repeated positioning accuracy X,Y,Z,W | mm | X:0.025 Y,W:0.016 | X:0.025/1000 Y:0.020 W:0.018 | X:0.025/1000 Y:0.020 W:0.018 | 0.013/1000 | X,Y,Z:0.015 |

| Machine tool overall dimension(L*W*H) | mm | 8000*2993*4500 | 8600*4490*4830 | 9300*5500*5600 | 8400*3200*5600 | 9000*3200*5600 |

| Weight of machine | kg | 28000 | 34000 | 42000 | 31500/34500 | 37000 |

| Total electric capacity | KVA | 50 | 70 | 85 | 85 | 85 |

| CNC system | SIEMENS 840D sl | SIEMENS 840D sl | SIEMENS 840D sl | SIEMENS 840D sl | SIEMENS 840D sl |

.jpg)