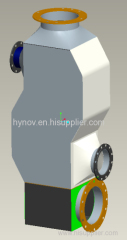

Non-ferrous Smelting Waste Heat Recovery

Company Profile

| Location: | Yancheng, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Waste Heat Boiler, Heat Recovery Boiler, Waste Heat Recovery, Waste He |

Product Description

Non-ferrous Metal SmeltingWaste Heat BoilerNecessityThe metallurgical process of non-ferrous metal consumes a lot of energy which accounts for 10% of the entire domestic energy input and 15% of domestic industrial energy input (2010). Approximately 60% of energy that is required in this process is regarded as waste heat,Website:http://www.chinawasteheatboiler.com, and 80% of this wasted energy is usually stored within the flue gas itself. Today, most of the flue gas produced from general non-ferrous metal smelting plants gets released into our atmosphere, which puts our environment at stake.Design IngenuityDuring the smelting process, flue gas quantity (high melt-ability) and temperature often fluctuate with the smelting cycle, rendering the boiler heat surface cleaning process difficult. Our waste heat boiler for this application features a dust settling chamber with a horizontal channel which is in direct contact with flue gas, and forced circulation mode. Heat surface area employs a simple but reliable vertical serpentine coil structure, and boiler wall structure is high quality membrane. It is because of our years of experience in the waste heat recovery sector, we are able to maintain the heat surface temperature higher than the dew point of gaseous sulfuric acid, which further guarantees the zero occurrence of corrosion. It is equipped with a rapping cleaning system. The average investment recovery period is around 2.5 years. Key ParametersRated steam pressure: 3.2 MPA ~ 4.5 MPARated steam temp: saturated steam temp ~ 450℃PROJECT NON-FERROUS METAL SMELTING WASTE HEAT RECOVERY (COPPER) FOR: BAIYIN HONGLU COPPER INDUSTRY LTD. Rated steam output: 10 T / H @ 1.27 MPA Rated steam temp: 194 Deg Celsius (saturated temp)