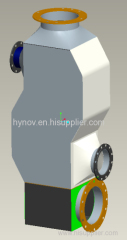

boiler flue gas waste heat recovery system

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | T/T |

| Supply Ability: | as request |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Foshan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Trading Company |

| Main Products: | Heat Exchanger For Air Compressor |

Product Detail

| Model No.: | HYNOV |

|---|---|

| Means of Transport: | Land |

| Production Capacity: | as request |

| Packing: | as request |

| Delivery Date: | in 30 days |

Product Description

The situation of energy conservation nowadays

In the present society, the energy conservation has become the fifth energy after coal, power, oil, and gas. There are still many problems in the use of industrial boiler, just like the low utilization of existent heat, the high temperature of the flue gas waste heat, the high content of air pollution and so on.

Nowadays, the industrial boiler is the primary motivity equipment of heat energy of my country, with the quick development of economic, the energy consumption is increasing and the worsening problem of city air quality is becoming more and more serious.

And one of the primary reasons of high pollution and energy consumption in motivity of heat energy is Flue Gas Emission. The Flue Gas Emission not only leads the direct pollutants Emission, but also increase air temperature by the high temperature itself.

In order to solve the problem of the direct fuel gas Emission, the boiler flue gas waste heat recovery system attracts more attention.

By recovering the boiler fuel gas, it not only reduces the direct emission of air pollutants, but also decreases the temperature of fuel gas.

The following is the technological principle of heat recovery:

The temperature of boiler fuel gas direct emission is up to 300-500℃, when it enter in air-to-air heat exchanger, it will exchanges the heat with the low temperature air.

the low temperature air absorb the heat of high temperature fuel gas fully, and its temperature can up to 200-350℃.

With the help of external mounted fan, it will enter high energy-efficient COMBUSTION gun.

The Scroll mixing structure strengthens the pre-mix between the high temperature air and gas, make the gas burn fully and improve the combustion efficiency.

More energy conservation solutions

In addition, if the factory has air compressors, we can also make energy efficiency renovations for air compressors, the heat exchange water up to 60℃ can be used in boiler hot water supplement.

This idea changes the traditional energy efficiency renovations, which uses the fuel gas waste heat to heat the hot water and then supply water to boiler. And this change makes more 10%-20% benefit on the basis previous.