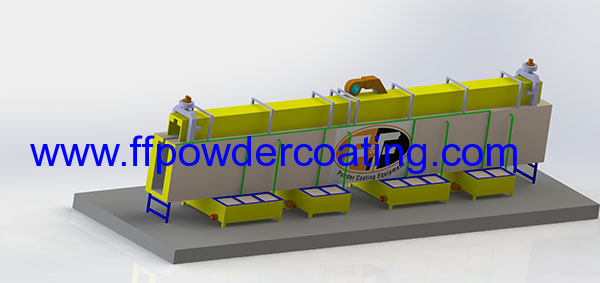

spray pretreatment powder painting line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 10 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | FF-P-3 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | FeiFu |

| Model Number: | FF-P-3 |

| application: | powder coating plant pretreatment |

| for part: | metallic |

| heating way: | electrical or gas |

| temperature: | room temperature to 60 degree |

| material: | stainsless steel |

| nozzle material: | plastic |

| pump: | Germany brand |

| Condition: | New |

| Production Capacity: | 10 |

| Packing: | packed the spraying system into container |

| Delivery Date: | 20 work days |

Product Description

spray pretreatment powder coating line

1. full spray treatment process, the rational use of production sites.

2. washing spray the reverse cleaning method, both to improve the quality of cleaning and water conservation.

3. Each sump with overflow tank and outfall, sewage clear slot is very convenient.

Spray Pretreatment Powder Spray Coating Line System Custom

Coating pre-treatment product before spraying process collectively, the conventional visible for degreasing rust and phosphate processing. Spray pre-treatment, as the name implies, is the use of high-pressure spray to phosphated metal components in the factory store, transport or machining of the workpiece, oil, rust formed in the surface layer (oxide), etc. . If the direct coating of the coating attached to these artifacts not only affect the coating adhesion, appearance, moisture resistance, corrosion resistance, and corrosion under the coating film to spread, resulting in the defects of the coating film peeling, blistering, even coating into a piece off. Therefore, only prior to coating, the workpiece surface oil, rust, or oxide, sand, welding slag, palmar attachments divisible, in order to prevent the coating blistering, loss and other undesirable phenomena occur, in order to improve the coating film adhesion and corrosion resistance.

Pre-treatment process purpose

(1) provides a clean surface;

(2) can significantly improve the adhesion of the workpiece surface;

(3) can exponentially increase the corrosion resistance of the coating;

(4) can improve the flatness of the workpiece surface and the decorated

(5) create a good base for painting.

Pretreatment process

Loading workpiece → degreasing spray (40-50 ° C 3.0min) → drip → the washing spray (RT 1.0min) → drip → washing spray (RT 1.0min) → dripping → Table tune spray (RT 1min) → drip → phosphating spray (35-45 ° C for 3 min) → drip → washing spray (RT 1.0min) → drip → washing spray (RT 1.0min) → the water dripping → drying (100-120 ° C 15 in) → spraying