powder coating production line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T, WU, Money Gram |

| Supply Ability: | 1PCS/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | FF-L-6 |

|---|---|

| Means of Transport: | Ocean |

| Brand name: | FeiFu |

| Line type: | vertical |

| Condition: | New |

| Spray machine: | Powder coating gun |

| The coating method: | electrostatic powder coating |

| Weight: | As per design |

| Power(W): | 50W |

| Voltage: | 380V |

| Type: | Coating Production Line |

| Warranty: | 1 year |

| Production Capacity: | 1PCS/month |

| Packing: | container |

| Delivery Date: | 40-60days |

Product Description

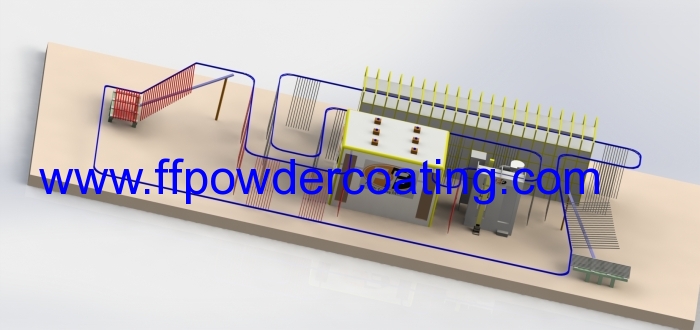

powder coating production line

powder coating production line consists of Powder Coating Booth, Reciprocator,

Automatic Powder Coating Gun, drying oven and curing oven, conveyor system and electric control system.

Design

1. According to the shape of workpiece, we design the pretreatment to you.

2. After cleaning, he pre-treated workpieces will be conveyed to drying furnace for water removal on their surface. The drying furnace is designed being tank type to match with immersion pretreatment tanks, and with a top-door design for easy access of pre-treated workpieces.

3. After drying, the workpieces are ready for powder particle adhesion. Please manually feed them on auto powder painting line. For a better painting result, the spray booth, waster powder recycling system, reciprocator adopts advanced equipments in China through our careful selection. And the spraying guns, both auto and manual are imported from foreign famous company for a longer service life. Then these workpieces will be sent to gas-fired furnace tunnel to let powder melt into a smooth coating.

Process:

Feed yourworkpiece on hanger for the preparation for cleaning

washing stage

Passivisation stage

washing stage

Drying off oven to remove surface moisture

Manually transfer the pre-treated objects to powder coating line

Powder application with spray guns

Powder curing

Finished product discharging