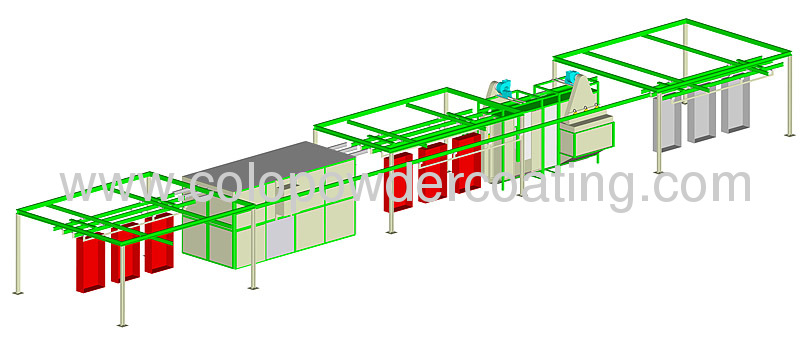

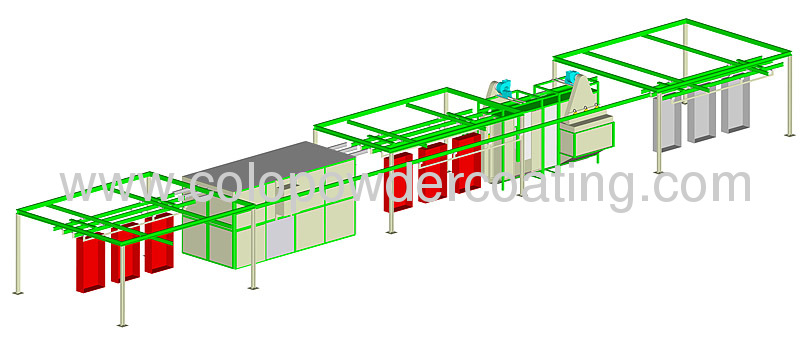

Powder coating production line for machinery

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 200Piece/Pieces Per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | COLO-L |

|---|---|

| Means of Transport: | Ocean |

| line: | powder coating |

| Extra Services: | Painting / Powder Coating |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal: | Aluminum |

| product max size: | L500mm*W600mm*H900mm |

| product max weight: | ≤30Kg |

| Conveyor chain single hanging weight: | 20 Kg |

| Design line speed and adjustable line speed: | 1.5m/min (0.3m-3.6m/min) |

| Compressed air: | the users themselves, freeze-drying, moisture content <1.3g/m3 oil content <1PPM |

| Production Capacity: | 200Piece/Pieces Per Month |

| Packing: | wood box or carton box |

| Delivery Date: | 15 days |

Product Description

Specifications

High Quality Automatic Powder Coating LineElectrostatic Spraying Process

electrostatic powder painting line

1. Pretreatment

Objective:To get rid of the workpiece surface oil, dirt, rust and in theworkpiece surface generating a layer of corrosion resistance and canincrease the spraying coating adhesion "phosphating layer".

2. Electrostatic spraying

Objective:Powder coating evenly spray to the surface of the workpiece. Thespecial work (including easy to produce electrostatic shieldingposition) should be using the high performance electrostatic spraymolding machine to complete the painting.

3. High temperature curing

Objective:The workpiece surface of powder coating heating to the specifiedtemperature and heat preservation corresponding time, melting, flowflat, curing.

4. Decoration processing

Objective:Make after electrostatic spraying after the workpiece to achieve a kindof special appearance (all kinds of wood grain, decorative pattern, suchas honor).