Compact powder coating line for aluminum profile

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, T/T, WU, Money Gram |

| Supply Ability: | 1PCS/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | FF-L-2016225 |

|---|---|

| Means of Transport: | Ocean |

| Design: | by F&F |

| Line type: | horizontal |

| product: | mental products |

| working voltage: | as request |

| spray booth: | fast color change |

| warranty: | 1 year |

| Certification: | CE |

| Powder coating: | automatic |

| Series: | powder coating equipment line |

| GUN: | automatic powder coating gun |

| Production Capacity: | 1PCS/month |

| Packing: | container |

| Delivery Date: | 45-60days |

Product Description

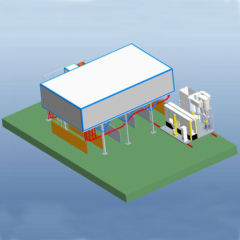

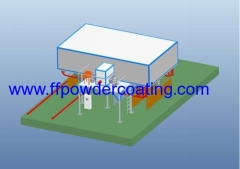

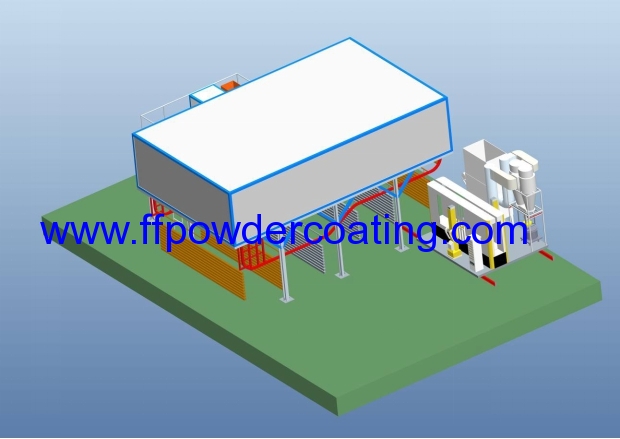

horizontal powder coating system for the aluminum profile

Our powder spray booth is easy to clean, resulting in a quick color change and is safe to operate. No powder spillage out of the booth .

The powder recovery system could be multi-cyclone, Mono-cyclone and filters.

Material of the powder spray booth could be plastic, stainless steel, powder coated carbon steel

Advantages of Compact powder coating line:

1,Only two operators are required for the whole plant

2,Given the small demensions of the booth a perfect cloud of powder is achieved which allow a uniform painting of the complete surface of the profile without need of any manual touch-up

3,Color change is carried our in a very quick and easy way thanks to the reduced dimensions of the booth walls

4,Very low energy consumption,thanks to the piece passage openning which are located on the bottom wall of the oven as the heat trends to rise

5,Thanks to the smal volume of the booth ,the suction and powder recovery system work perfectly,thus permitting a very reduced powder consumption

6,If the plant is equipped with two booths,while one is working ,the second can undergo cleaning without any downtime for color change.

7,Very reduced space is required to install the plant.

Powder coating line for Aluminum profile Drawing

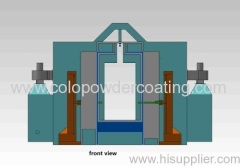

Compact powder coating line with stainless steel booth

stainless steel booth+mono-cyclone recovery +reciprocator+control panel

mono-cyclone recovery +reciprocator+control panel