Down feather jacket filling machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | T/T |

| Supply Ability: | 1000pc/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Pillow Filling Machine, Fiber Opening Machine, Ball Fiber Machine, Fiber Filling Machine, Plush Toy Stuffing Machine |

Product Detail

| Model No.: | DF2 |

|---|---|

| Means of Transport: | Ocean |

| Use: | Others |

| Type: | Others |

| Brand Name: | Tokays |

| Function: | Down feather jacket filling machine |

| Production Capacity: | 1000pc/month |

| Packing: | MDF wooden carton |

| Delivery Date: | 30days |

Product Description

1. Keep workplace clean

2. Only need 1 operator, 2-4 times faster than manual work

3. Filling Speed:1 g/s~8g/s(adjustable)

4. Accurate quantitative precision can be 0.01g

Model | DF2-1 | DF2-2 |

Filling nozzles | 2 | 2 |

Filling material | 90, 80, 70, 60, 50 down (dry) | |

Dimension | Main body tank: 2.4m*0.85m*2.1m Weighing tank: 1.6m*0.55m* 1.1m Occupancy: 2.5m*3.2m Recommended space min. 4m*6m | Main body tank: 2.2m*0.85m*2m Weighing tank: 1.6m*0.57m* 0.9m Occupancy: 2.2m*3.2m Recommended space min. 3m*5m |

Recycle times | 3 | 3 |

Weighing scope | 0.2-30g | |

Weighing accuracy | 0.01g | |

Filling speed | 1g/s-8g/s (adjustable) | |

Down loading | 10kg-12kg | 8kg-10kg |

Pressure detecting system | Yes | Yes |

Constant humidity system | Yes | No |

Down refund and supplemented system | Yes | Yes |

Down material change by one-click | Yes | No |

Air pressure | 1. Min. air supply volume of air-compressed air pump: above 0.8m3/min 2. Above 7.5kw, independent supply. (please ensure enough air supply if share air supply) 3. High pressure air pump (1.0Mpa) is recommended and operating air pressure min. 0.58Mpa 4. Gas storage tank (buffer tank): above 0.6m3, used for stabilizing pressure and prolonging service life of air compressor. | |

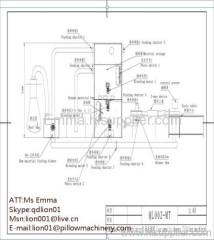

Down feather jacket filling machine

Function: machine for goose or duck down feather filling for jacket, garment, sleeping bag etc.

High efficient & labour saving: 2-4 times faster than manual work, 2 workers can support 5-7 assembly lines.

Accurate quantitative precision: non-contact weighing method, highest precision of single down filling can reach 0.01g.

Capable for large and small lattice panels: 0.2-32g

Healthy & environment-friendly: Dust-removal system & recycle down

Patented design of down outlet: easy for breathable & non-breathable fabrics.

Friendly touch screen: data storage, data revision, on-time insight.

Fully automatic & No need skilled labor.

Details

Working Principle: High-pressure air is used to absorb down through the automatic weighing system,and to fill the panel with preset weight of down.

Scope of Aplication: It is applied in down garments manufacturers' filling process, and is applicable to 90,80,70,60 and 50 down.

Filling Port: Two under independent operation. Each panel piece can be set to 100 grid grams. It can save up to 100 sets of data for different panels.

Filling Speed:1 g/s~8g/s(adjustable)

Down mixture: 90,80,70,60,50 down,dry

Accuracy for one whole jacket: ±3%(90 down under standard environment testing)