Feather & down filling machine

30000.0~60000.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 10pcs/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Fiber Ball Machine, Pillow Filling Machinery |

Product Detail

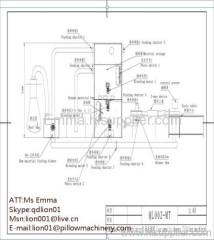

| Model No.: | QL002-MT |

|---|---|

| Means of Transport: | by sea |

| Use: | Others |

| Type: | Nozzle |

| Brand Name: | LION |

| Production Capacity: | 10pcs/month |

| Packing: | wooden case |

| Delivery Date: | 50days |

Product Description

Specification:

Item no.: QL002-MT

Layout dimension: 6000*2500*3600mm

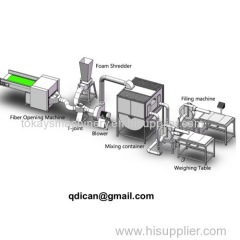

Equipment: Raw material box with paddle; Mixer with vacuum feeding system; Blower; Filling table 1nozzle

Voltage: 480v 60Hz 3phase

Power: 9.5kw

PLC: Siemens

Material: Down\feather

Hopper capacity: 10-15kg

Hopper capacity: 10-15kg

Air pressure: 0.6-0.8Mpa

Capacity: Min.60-80kg/h

Operator: 1 person

Weight: Min. 1.1 ton

Description:

The down and feather filling machine can be used for pillow, cushion and comforter.

It can be used with down, feather and micro fiber.

QL002-MT is assembled with a material storage, material transporter, filling device, electrical scale and recycle dust collection system.

The whole line is controlled by Siemens PLC control system that can be handled by only 1 operator.

First of all put the raw down material into the raw material storage where has one blender to move the material running, so that can be easily suck by the transporter.

The material will be transported to the mixer automatically.

There are 2 sections inside of the mixer that contains about 10 to 15kg once a time. Choose raw material feeding from the control screen against the alarm system as soon as material low.

The top section of the mixer keeps the raw material and feeds the material to the bottom section by the sense of the density sensor.

There is a blending device in each section of the mixer to keep moving of the material.

First of all set up the test time from the control screen-testing mode such like 5 seconds and get to know how much can be filled within 5 seconds from the scale.

The PLC will make record automatically after few times of testing.

Calculate how much do you need to fill per section and set up the volume from the control screen and then start producing.

From the recycle dust collection system the filling waste will be suck and feed back the raw material automatically, so that keeps your operation environment clean.