Diamond Grinding wheel Sales Service

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50000pcs/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Diamond , Diamond Drill Bit, Diamond Saw Blade, Diamond Grinding Wheel Series, Diamond Grinding Disc Series |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | HE HUI |

| high efficiency: | good sharpness |

| long life: | sizes could be customized |

| Production Capacity: | 50000pcs/month |

| Packing: | independent packing |

| Delivery Date: | 15-30days |

Product Description

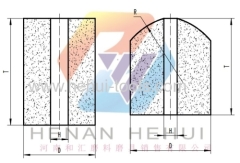

1. Application: Used for the high efficiency and abrasive machine of main journal, connecting bar journal of the engine crankshaft and its capped edge.

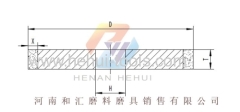

2. Specification

Shape code | D | T | H | X |

1A1 | 500 | 20,24 | 203,304.8,305 | 5,8,10 |

1A1 | 600 | 20,23,35 | 132,304.8,305 | 5,10 |

1A1 | 650 | 43.5,47.5,50.5 | 132,152.4,304.8 | 6,11 |

Other sizes could be offered as per requirement. | ||||

3. Features of the vitrified CBN grinding wheel

l Hardness and brittleness of the vitrified bond has been well kept

l Mature sintered technology, good bond with diamond frit

l Reasonable porosity and pore size, makes the grinding wheel get good self-sharpness, long life

l Silent working, little pollution

l High accuracy

4. Ordering example

Unit:mm

Name | Shape code | D | T | H | X | Abrasive | Grit | Bond | Concentration | Hardness |

Vitrified CBN grinding wheel | 1A1 | 650 | 43.5 | 304.8 | 11 | CBN | 120/140 | V | 175 | J |

5. Procedure for ordering

Order→formula&design→raw material inspection→producing working layer→QC for semi-finished product→machining→Quality control→Delivery for qualified product→After sale service

6. Quality control:

① Raw material inspection. Sampling inspection is done for each batch of raw material

② Strict producing procedure, detailed production record. Real time report for abnormal phenomena.

③ Strict quality control

④ Periodical survey for the stability

⑤ Rotary test is done for each single piece of grinding wheel for make sure the safety

7. After-sale service

Calling or visiting customers for feedback. Problems will be solved immediately once found.

we are seeking global co-operation agents for our products