Diamond Grinding wheel Sell Service

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50000pcs/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Diamond , Diamond Drill Bit, Diamond Saw Blade, Diamond Grinding Wheel Series, Diamond Grinding Disc Series |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | HE HUI |

| high efficiency: | good sharpness |

| long life: | sizes could be customized |

| Production Capacity: | 50000pcs/month |

| Packing: | independent packing |

| Delivery Date: | 15-30days |

Product Description

1. Application: the grinding wheel is used for the inner circle and groove of compressor etc.

2. Advantages of CBN itself:

High hardness(ranged second for harness in nature), high toughness, good thermal stability (1250-1350℃). And its good performance when processing iron and other thermal sensitive material makes it work with high speed and there is no sticking chip.

CBN is with good chemical inertness, so there is little chance for the happening of chemical reaction when processing iron. Thus the sharpness could be greatly kept, and the surface accuracy or roughness of the work piece could be greatly assured.

Good heat conductivity, little residue stress, good shape keeping, and little burning of the surface.

Good abrasive weariness, long working life.

3. Features of the vitrified CBN grinding wheel

Hardness and brittleness of the vitrified bond has been well kept

Mature sintered technology, good bond with diamond frit

Reasonable porosity and pore size, makes the grinding wheel get good self-sharpness, long life

Silent working, little pollution

High accuracy

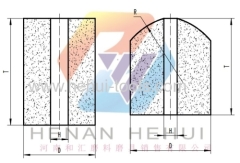

4. Selecting for suitable grinding wheel for inner circle and groove

Different materials like bearing steel, cast iron, high speed steel, mould steel etc are with different features, like the hardness. In order to raise the production efficiency and lower the cost, the following information should be offered before selecting the right grinding wheel:

Material, item No. and hardness of the work piece should be offered

Required surface accuracy

Feeding speed

Grinding output

Linear speed

Capacity for per piece of grinding wheel

Item No. for grinding machine

Cooling

5. Ordering example

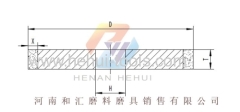

Unit:mm

Name | Shape code | D | T | H | X | Abrasive | Grit | Bond | Concentration | Hardness |

Vitrified CBN grinding wheel | 1A8 | 22 | 16 | 1.5 | 20 | CBN | 120 | V | 150 | N |

Sizes could be offered as per requirement.

6. Procedure for ordering

Order→formula & design→raw material inspection→producing working layer→QC for semi-finished product→machining→Quality control→Delivery for qualified product→After sale service

7. Quality control:

① Raw material inspection. Sampling inspection is done for each batch of raw material

② Strict producing procedure, detailed production record. Real time report for abnormal phenomena.

③ Strict quality control

④ Periodical survey for the stability

⑤ Rotary test is done for each single piece of grinding wheel for make sure the safety

8. After-sale service

Calling or visiting customers for feedback. Problems will be solved immediately once found.

we are seeking global co-operation agents for our products