Diamond drill Sales Service

| Min. Order: | 10 Pack/Packs |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50000pcs/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Diamond , Diamond Drill Bit, Diamond Saw Blade, Diamond Grinding Wheel Series, Diamond Grinding Disc Series |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | HE HUI |

| high efficiency: | good sharpness |

| long life: | sizes could be customized |

| Production Capacity: | 50000pcs/month |

| Packing: | independent packing |

| Delivery Date: | 15-30days |

Product Description

1. Application: Vacuum brazing diamond core bit is used for the wet/dry drilling of ceramic, stone like granite etc.

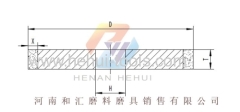

2. Specification:

Art No. | Dia. mm | Segment Length mm |

HHD-VBD-005 | 5 | 3, 5, 8, 10 |

HHD- VBD -006 | 6 | 3, 5, 8, 10 |

HHD- VBD -008 | 8 | 3, 5, 8, 10 |

HHD- VBD -010 | 10 | 3, 5, 8, 10 |

HHD- VBD -012 | 12 | 3, 5, 8, 10 |

HHD- VBD -013 | 13 | 3, 5, 8, 10 |

HHD- VBD -015 | 15 | 3, 5, 8, 10 |

HHD- VBD -016 | 16 | 3, 5, 8, 10 |

HHD- VBD -018 | 18 | 3, 5, 8, 10 |

HHD- VBD -020 | 20 | 5, 8,10,12,15 |

HHD- VBD -022 | 22 | 5, 8,10,12,15 |

HHD- VBD -025 | 25 | 5, 8,10,12,15 |

HHD- VBD -028 | 28 | 5, 8,10,12,15 |

HHD- VBD -030 | 30 | 5, 8,10,12,15 |

HHD- VBD -032 | 32 | 5, 8,10,12,15 |

HHD- VBD -035 | 35 | 5, 8,10,12,15 |

HHD- VBD -040 | 40 | 5, 8,10,12,15 |

HHD- VBD -045 | 45 | 5, 8,10,12,15 |

HHD- VBD -050 | 50 | 5, 8,10,12,15 |

HHD- VBD -055 | 55 | 5, 8,10,12,15 |

HHD- VBD -060 | 60 | 5, 8,10,12,15 |

HHD- VBD -068 | 68 | 5, 8,10,12,15 |

HHD- VBD -070 | 70 | 5, 8,10,12,15 |

HHD- VBD -080 | 80 | 5, 8,10,12,15 |

HHD- VBD -090 | 90 | 5, 8,10,12,15 |

HHD- VBD -100 | 100 | 5, 8,10,12,15 |

HHD-VBD -110 | 110 | 5, 8,10,12,15 |

HHD- VBD -120 | 120 | 5, 8,10,12,15 |

Marks: Diameter from 5mm to 16mm could do wax filling which is specially designed for dry use.

3. Features:

Both wet/dry use

Very good sharpness

Long life span

Connection could be M14, 5/8-11UNC, hex, round etc, also could be customized

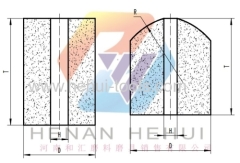

Advantages of vacuum brazing technology

Good bonding strength between diamond and the shank, all diamond is bonded to the shank through chemical metallurgy melting, there will be no diamond dropping off during work. Thus some tools could be used for dry.

About 70-80% of the total height of the crystal is exposed outside, this guarantees good sharpness of the tool and most of the diamond is made good use of. Besides, the space makes the chip removing easy.

Vacuum brazing technology is environmental friendly, and diamond from 30#-100# could be vacuum brazed.

4. Service

Wide range of products with complete specification

Packing: independent packing

Delivery time: within 15-30days

we are seeking global co-operation agents for our products