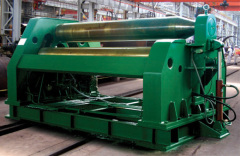

Corrugated Sheets Roll Forming Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 1-60 sets / quarter |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | C Purlin Roll Forming Machine, Z Purlin Roll Forming Machine, C And Z Purlin Interchangeable Roll Forming Machine, Metal |

Product Detail

| Model No.: | Customized |

|---|---|

| Means of Transport: | Ocean |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Roll Forming Machine |

| Extra Services: | Cut To Length |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Others |

| Brand Name: | Believe Industry |

| Production Capacity: | 1-60 sets / quarter |

| Packing: | Nude Packing |

| Delivery Date: | 60 days |

Product Description

Description:

The Corruagted sheets roll forming machine is widely used in South Africa. The Corrugated

profile virtually eliminates oil canning and the sheeting can be factory cranked, curved and

bullnosed to various radii depending on customer's requirements. The overall width of a

8.5 Corrugated sheet is 700 mm and a 10.5 Corrugated sheet is 840 mm.

Structural guidelines:

Corrugated roof sheets are available in a wide range of materials displaying various

structural properties. It should be noted that the load span characteristics are only to

be used as a broad guideline as purlin spacing is also dependant on other factors such

as the prevailing winds in a certain area, the presence of dust and other particles in

industrial areas, the type of structure that is being erected etc. We therefore recommend

that an engineer is consulted to determine the purlin spacing for a specific application.

Uncoiler: Manual Uncoiler

Coil Inner Diameter: 508-610mm

Coil Outer Diameter: max 1500mm

Loading Weight: 5T

Roll Forming Machine

Main Structure of the Machine: 36# "H" Beam Steel

Rolling Stations: 16 stations (subjected to final design)

Forming Speed: Approx. 10-12m/min.

Diameter of Shaft: 75mm

Tolerance of Shaft Dia.: +0-0.03mm

Material of Shaft: 45# steel with heat treatment HRC50~55

Material of Roller: 45# steel with quenching treatment and chroming of 0.05mm thickness

Tolerance of Roller Hole Dia.: +0.03-0mm

Transmission: Chains-bracket

Motor Power:5.5KW (subjected to final design)

Brand Motor: Chinese Guomao

Hydraulic Cutting Device

Material of Cutting Mold: Cr12 Steel with quenched treatment HRC 60-62

Cutting Length and Quantity: Clients can set the length and quantity on the PLC touch screen

Hydraulic Station Power: 3KW (subjected to final design)

Tolerance of Cutting Length: +/-2mm

Control System

PLC Control Box: 700mmx1000mmx300mm

Computer Control System:Panasonic PLC

Encoder: Omron Brand

Pressure of Hydraulic Station: ≧16Mpa

Current: 380V direct current, 50Hz, 3 phase