Corrugated Sheet Roll Forming Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 200 sets for a year |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | TBD |

|---|---|

| Means of Transport: | Ocean |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Roll Forming Machine |

| Extra Services: | Cut To Length |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | MTC |

| Control System: | PLC |

| Drive System: | Chain brackets |

| Production Capacity: | 200 sets for a year |

| Packing: | nude packing, loading in full container directly |

| Delivery Date: | 45 working days |

Product Description

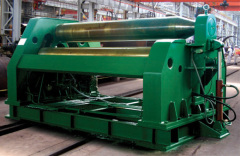

Picture For Reference Only.

Corrugated Sheet Roll Forming Machine is warmly welcomed all over the world because the appearance of the corrugated roofing sheets is a beautiful landscape in steel building industry. The roofing sheets produced by the corrugation sheet roll forming machine are called ONTU roofing sheets in South/North America and Sino-roofing sheets in Indian markets. The corrugated sheet roll forming machine is highly popular in African markets and east European markets where people favor using the wave roofing sheets.

Below is One Machine General Parameters for Reference Only.

Material Width: 762-1220mm

Effective Width: 610-1035mm

Thickness of Coil: 0.3-0.8mm

Forming Stations: 16-18

Forming Speed: 8-12m/min

Main Power: 5.5KW

Hydraulic Power: 4KW

The Overall Dimensions: 9200mmX1500mmX1300mm

Total Weight: Approx.7T

WE CAN ALSO MANUFACTURE ACCORDING TO CUSTOMER'S DRAWING AND REQUIREMENT.