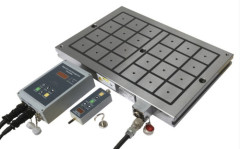

Electric permanent magnetic chuck

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

|---|---|

| Supply Ability: | 100 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | EP75-406 |

|---|---|

| Means of Transport: | Express, Air, Land |

| Series: | EP75 |

| Pole size: | 75mmX75mm |

| Nominal holding force: | 15-17kg/cm2 |

| Processing: | Milling and CNC machining |

| Use: | Various dimensions |

| Production Capacity: | 100 sets per month |

| Packing: | wooden box |

| Delivery Date: | 20 days |

Product Description

Electric permanent magnetic chuck(EP75 Series)

DESCRIPTION :

1.Comprising 75mm*75mm poles with a force of 15-17kgf/ cm2.

2. It is possible to predetermine the force generated by counting the number of poles,

work piece gripping at least 4 pole contact faces.

3.Controller do the Magnetizing or demagnetizing in 0.5~5 seconds.

4.Chuck is tested for Slippering force, Waterproof test, Temperature rise test, Electrical & Demagnetizing tests

USE:

1.Used for normal and heavy duty drilling, milling, and CNC machining center

2.Best used for the workpieces at least 400*400 mm and 18 mm thick,Ideal for general pieces of various dimensions with normal operating air gaps and medium thicknesses

Standard Features and Benefits:

1.Flexibility :

• Allow single set-up machining with 5-sided accessibility

• workpieces larger than the table are machinable

2.Safety

• No electric power supply during clamping

• Constant and uniform magnetic power over entire area.

• No temperature rise in operation. so no impact on precision and work piece deformation due to temperature rise.Can used for long time.

3.Efficient

• Easy and quick position,reduce set-up time and increase available machine time.

• High accuracies and tolerances

4.Cost-effectiveness

• no maintenance

• no machine modifications

• reduced tool consumption

Specs:

Other size on request

Aplication:

.jpg)