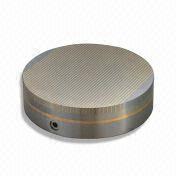

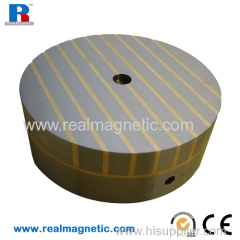

Round permanent magnetic chuck

0.1~100.0 USD

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 800 tons/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Ndfeb Rare Earth Magnet, Hard Ferrite Magnets, Ring Sintered Alnico Magnet, SmCo, Flexible Magnets |

Product Detail

| Model No.: | MC002 |

|---|---|

| Means of Transport: | Ocean, Air |

| Specification: | Strongly magnetized |

| Shape: | Round/Circular |

| Composite: | NdFeB magnets |

| Application: | Industrial magnet |

| Place of origin: | Ningbo |

| Production Capacity: | 800 tons/year |

| Packing: | paper-vacuum-box |

| Delivery Date: | 25 days |

Product Description

Round Magnetic Chuck/Circular Magnetic Chuck/permanent magnetic chuck

1.General Introduction

1), Round permanent magnetic chuck (circular magnetic chuck) can be used as auxiliary tool for various kinds of plain surface grinder, universal tool and lathe for holding ferromagnetic materials for machining.

2), Because it does notrequire power source, not heated and is with small distortion and high precision, the application field is very wide.

3),According to its structure, the circular permanent-magnetic chuck can be classified as straight strip fine-pole type, ordinary pole type and radial pole type.

3.Types:

4.Features:

2.Material: Nd- Fe- B alloys

3.Types:

a) Round Permanent Magnetic Chuck,

b) handle magnetic chuck,

c) rectangle steel permanent magnetic chuck,

d) Sine Table with Magnetic Chuck,

e) Double Plates Magnetic Chuck,

f) leaning permanent magnetic chuck,

g) circular magnetic chuck,

h) wire-cutting versatile chuck,

i) grinding wheel dresser,

j) magnetic V-block,etc

4.Features:

a)Large effective area for machining the work pieces;

b)Positive locking at all angles without any distortion;

c)Constructed of hardened alloy tool steel.;

d)Angle precision 0.007/ 100mm;

e)Low height for more wheel clearance;

5.Daily Maintenance:

a)Clean the work-surface of magnetic chuck in order to avoid rusting on the surface.

b)Frequently check the work-surface of magnetic chuck if have spoil and scratch.

Because these will effect its attractive power and work-piece's required tolerance.

c)To cover with anti-rust grease(oil) on the work-surface if no use for long time

.jpg)

.jpg)

.jpg)