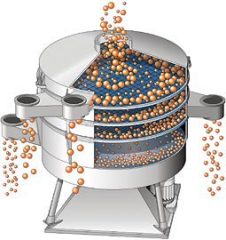

Metal powder rotary sieve vibrating screen

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets in one month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | DH-400-2s |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Diameter: | 350mm |

| Power: | 0.18KW |

| Layer: | 2 |

| Voltage: | 380V |

| Volume: | 580*580*670 |

| Material: | contact part is stainless steel |

| Production Capacity: | 100 sets in one month |

| Packing: | Free fumigation wooden cases |

| Delivery Date: | 7-10 days afte receivng your deposite |

Product Description

Metal powder rotary sieve vibrating screen work principle

Its vertical motor, which is installed eccentric hammers on the top and bottom, is regarded as a vibratory source. The eccentric hammers change rotation into horizontal, vertical and inclined movement, and then pass the movement to the sieving surface. The materials though inlet into internal equipment. According to the different material screening requirements. In the process, bouncing balls stike screen continually by frequency vibration to make materials on the upper layer pass the screen, It can effectly solve blocking problem, after differient mesh materials pass differient mesh, materials discharge from layers.

New sieve separate design advantage

1Save time(3-5 minutes to complete screen replacement).

2.Save manpower, two persons change screen

3.Increase production line fluency.

4.Increases screen life. Bouncing ball does not directly strike mesh.

5.Increase area.

It is easy and simple to change screen, just following the below way, no more than five minutes, It will be finished.

Mechanical installation and adjustment

1. There should be a stabilized base for equipment. When the equipment is installed on the ground or cement, it need not install bottom screw. When the equipment install on steel structure frame, screws should be fixed on the steel structure frame, and the steel structure should have a certain thickness.

2.Before the equipment is shipped from factory, it has installed screen,customers can change screen by yourselives during the using.

3. Before starting, customers should first check degree of fastening bolt and whether mouth position connect with stock receiver. Observe whether vibration motor can move and check whether each layer sieve is fastened.

4. Before the vibration sieve access electrical control panel, firstly, check the electrical control panel. After line connected, observe whether vibration motor rotation direction is clockwise. Wether pperation is normal and there is no noise.

5. Adjusting vibrating motor phase angle to fit all kinds of material screening.

Pls provide the following information for us.

1. material name.

2. the necessary capacity you required(per hour)

3. Machine material. Pls choose one:

a. All stainless steel 304

b.The contacting part is stainless steel, the other parts is carbon steel.

4. the dimension of the machine can be designed for you.

5. Additional parts ,like the mobil wheel, removing-dust hole and noise-proof base,can be easily fixed and maintained.

6. How many layers you need??

7. Pls inform the voltage&frequency in your city.

If you want to know more information about our product, please reference http://www.xxdahan.com