Tianyu Brand High Quality Rotary Vibrating Screen

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 set per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Vibrating Screen, Grain Cleaning Machine, Peanut Sheller, Peanut Picker, Peanut Cleaner |

Product Detail

| Model No.: | XZS |

|---|---|

| Means of Transport: | Ocean, DHL, Air |

| Application: | Ore |

| Type: | Separator |

| Brand Name: | Tianyu |

| Company history: | 11 years |

| Material: | SUS304 or carbon steel or optional |

| Color: | Blue, white or optional |

| Layer: | 1-3 |

| Mesh size: | 0-400mesh |

| Sieve diameter: | 200-2000mm |

| Voltage: | 380V or optional |

| Power: | 0.4-3.7Kw |

| Applied field: | Metallurgy, Chemical, Pharmaceutical, food industry and so on |

| Certificates: | ISO&CE |

| Production Capacity: | 100 set per month |

| Packing: | Crate case, fumigation-free wooden case or container |

| Delivery Date: | 10-15 working days after prepayment |

Product Description

XZS Rotary Vibrating Screen

Let's start the journey of exploring our product.

XZS Rotary Vibrating Screen

Introduction

This 3D rotary vibrating screen ,which makes use of upright motor as the source of vibration ,is suitable for the quick separation and filter of any powder, grain, liquid in the foodstuff, chemical pharmaceutical, grinding, ceramic and metals processing,etc.

Working principle

Its vertical motor, which is installed with eccentric hammers on the top and bottom, is regarded as a vibratory source. The eccentric hammers change the track of rotation into horizontal, vertical and inclined movement, and then pass the movement to the sieving surface. Adjusting the phase angle between the top and bottom eccentric weight can change trajectories of the materials on the sieve.

Applied field

Many kinds of the materials within 0~400 mesh like dry, wet, refined, coarse, heavy and light as well as those within 0~600 mesh like liquid and pasty materials can be screened by the machines. Details are as follows:

1. Chemical industry: resin, pigment, medicine, grease, extinction agent, rubber and plastic.

2. Abrasive, glass and ceramic professions: silicone sand, aluminum oxide, grinding abrasive, glass dust and fire-proof material.

3. Foodstuff: sugar, salt, alkali, glutamate, starch, powdered milk, soybean milk, yeast and fruit juice.

4. Papermaking profession: coated slurry, black and white liquor, padding fluid, waste liquid and waste water recycling.

5. Iron-smelting and mining industry: quartz sand, ore, titanium oxide and zinc oxide.

6. Mechanical profession: casting sand, powder metallurgy, electromagnetism material, aluminum powder, metal powder and alloy.

7. Environmental protection: trash, human and animal fecaluria, industrial waste water , food waste water and waste water processing.

8. Others: carbon black, activated carbon and pearl.

Feature

1. High efficiency, compact design and durability.

2. The unique grid design, shorten the time for net works, easy to operate.

3. Full sealing, and no powder overflow.

4. The material discharged automatically, you can work.continuously.

5. Make use of vertical vibration motor, mechanical drive, the transfer process without loss of the exciting force, the effective transfer to the screen surface.

6. Small size, take up little space, easy to move.

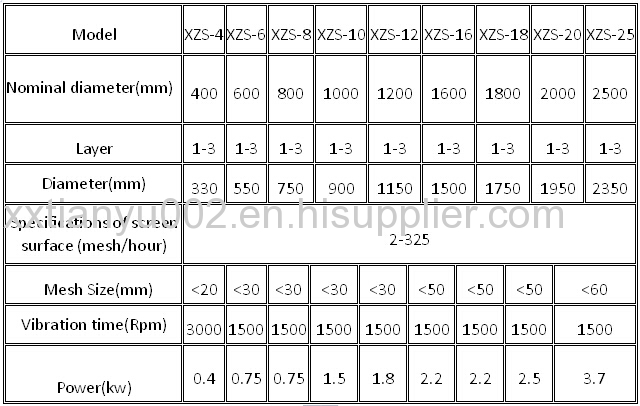

Technical parameter

Assembly picture

Product showcase

Customer design and dispatching

1.For export,we usually use different packs for different products according to its size.

2.For small size,crate case is adopted.

3.For big size and heavy good,fumigation-free wooden case or pallet is offered for 20' or 40' container or bulk shipment.

4.Five years export experience guarantees you to get your goods safely and quickly.

Do you have questions?Pl refer to our FAQ.

1.Q: We need a screen machine to sieve powder and can you please recommend the best type of machine for this application?

A: Please provide the following information to help us recommend a right unit for you:

1.Material to be processed?

2.Using purposes: to grade or to remove dusts?

3.Granule size of the materials? (Or mesh number)

4.Moisture content if any?

5.Granule size proportion if possible to get?

6.Capacity (tons or kg or litter per hour or day)

7.Local power supply (voltage and frequency)

2.Q: When can you deliver the machine?

A: We can produce it within 15 days from receipt of 40% deposit,for eg, it needs 15 days to the destination-Chennai port,so the total time is about 30~35 days from production to your port.

3 Q:Does your machine have any unclocking mechanism?

A:Not any. We have good sealing system and professional design for our machine.

We can show you as our video and drawing.

4 Q: We have a trouble for the screening machine we presently use.We find mesh-blocked phenomenon. Can you help us?

A: 1.The cleaning system (including the rubber ball and PU ring) is not good.

At first, you should purchase the good quality of cleaning system. You should change all of them once within 3~5 months.With professional design, we can guarantee 95% sieving efficiency and no blocking.

5.Q: Also, we need the equipment to be mobile, moving from one room to another room. Can you do it?

A: Yes. we can. Add wheels to the bottom.

For more , please contact us!

Our company

You may be also interested in our other products: