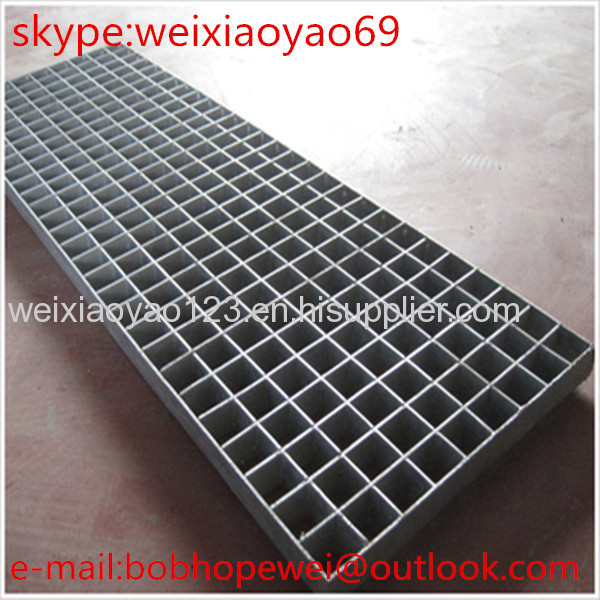

Floor Hot-dipped Galvanized Steel Grating

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 92 Ton/Tons per Day |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Wire Mesh , Metal Wire Mesh , Window Screen , Filter Wire Mesh |

Product Detail

| Model No.: | HY |

|---|---|

| Means of Transport: | Ocean |

| Application: | Others |

| Type: | Welded |

| Material: | Others |

| Brand Name: | HY |

| Mesh Size: | 1m*2m |

| material: | hot-dipped galvanized |

| size: | 32*5mm |

| Production Capacity: | 92 Ton/Tons per Day |

| Packing: | Bundles in container |

| Delivery Date: | 10-30 days |

Product Description

Steel Grating/Electro Galvanized Steel Grating/Hot-dipped Galvanized Steel Grating Bar/Serrated Steel Grating/Spray Coated Steel Grating

There are mainly Two types of steel grating: Common steel grating and serrated steel grating.

1. Common Steel Grating

(1) Welded Bar Grating

The most economical choice of steel grating product. This grating is manufactured by an electro-forging process, welding rectangular bearing bars and cross rods. This welding method provides a positive fusion of cross rods and bearing bars. The most popular is the 19-4 spacing; with approximately 80% open area the 19-4 spacing allows for passage of dirt, snow, liquids, air and debris. Welded bar grating is also available in close mesh ADA conforming spacing for use in public areas. Different bearing bar thickness can be specified, the most common 3/16" is stocked in multiple depths. 1/8", 1/4" are stocked in limited quantities. Bearing bar thickness is offered from 1/8" to 1/2" to accommodate any load rating requirements. Universally used in most general industrial plants as well as commercial buildings; it has a wide range of uses such as walkways, platforms, safety barriers, ventilation grates, and drainage covers.

2) Heavy Duty Grating

Heavy-Duty is typically 1/4" or thicker bearing bars. Depths range from 1" to 6", deeper bearing bars can be custom fabricated upon request. These heavy duty gratings are used mainly in parking lots, railroad yards, truck and bus terminals, industrial plants, highways, airfields, reinforced concrete areas, inlet covers, ventilation grilles, trenches. Heavy duty grating is available in a number of spacing options. When rolling wheel loads are to be used, we recommend the grating to be load banded to add lateral strength. Serrations are available on bearing bars up to 3/8" thick.

(3) Press-Locked Bar Grating

This grating is a system of interlocking, perpendicular bars, it provides a smooth clean look ideal for architectural applications such as grilles, divers and screens. It is used in the same structural applications as its welded steel counterpart. It is offered in a range of spacing options from 7/16" to 1-3/16". Press-Locked grating is not recommended for rolling loads. Instead of welding the joints, tremendous hydraulic pressure is used to bond the two close-tolerance slotted bars together. Permanent locking is achieved by forcing the deep cross bar into the notched bearing bar.