0.45mm Solar EVA film

| Min. Order: | 100 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 300000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | DK020 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | DK |

| SIZE: | 0.45MM*1M*100M |

| material: | Eyhylene Vinyl Acetate |

| Curing temperature:: | 135-140 degree |

| Certificate: | TUV |

| Shelf life:: | 6 months |

| Solidify time:: | 10-15 minutes |

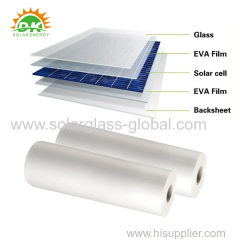

| Usage: | eva solar film for solar panel encap |

| Vacuum time: | 4-6 minutes |

| Production Capacity: | 300000 |

| Packing: | paper carton |

| Delivery Date: | 5-10days after receive the deposit |

Product Description

0.45mm Solar EVA film

Specification

Please find EVA Solar Module Film Details below:

| Item Name | EVA Solar Module Film |

| Thickness (mm) | 0.30-0.50 mm |

| Width (mm) | 300-1000 mm |

| Length per roll (m) | 100m, 150m |

Technical Data

| Item | Unit | Fast Cure |

| VA Contents VA | % | 30 |

| Melting Point | ℃ | 72 |

| Light Transmittance | % | >91 |

| Density | g/cm3 | 0.96 |

| Specific Heat | J/℃·g | 23 |

| Heat Conductivity | W/mk | 0.3 |

| Glass Transition Temp | ℃ | -40 |

| TensileStrength at Break (after cross-linking) | Mpa | 20 |

| Water Absorption | % | 0.01 |

| Cross-linking rate | % | >80 |

| Adhesive Strength(First EVA-Glass) | N/cm | >40 |

| Adhesive Strength(First EVA-TPT) | N/cm | >50 |

| Light Resistance(UV Radiation 1000hr) | %Retention | >90 |

| Damp Heat Test(1000hrat+85℃,85%RH) | %Retention | >88 |

| Shrinkage Rate(120℃,3min) | MD% | <4.0 |

| CD% | <2.0 |

• excellent adhension after aging, guarantee the 25 years quality outdoor using.

• low shrinkage , can guarantee the quality after lamination.

• Fast Cure,Increase the producing rate when laminated.

• Excellent weather resistance(Including high temperature and high humidity resistance

and UV )

• High transparence, insure the maximum power of module,deduct the cost of solar

module investors.

• Can good match with many different kinds of backsheet .

Storage and using:

1. store in cool and dry in the room temperature, temperature ≤ 30 ℃, humidity ≤ 70%; the shift time is

six months; suggest use up within three months..

2. product long-term stacking height, should not be too high, below five layer is ok ,it can

avoid bending deformation under the heavy pressure.

3. It is recommended that do not use the innermost and outermost circle,

4. don't make the product moisture, after opening the roll or cut a good film, is proposed use up within

48 hours .

Pcaking and shipping