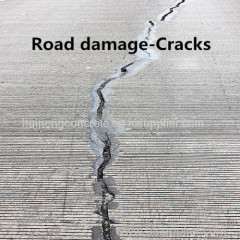

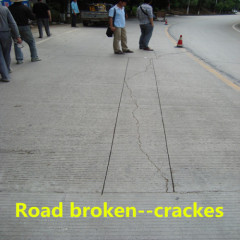

How to Caulk and Seal Cracks in a Concrete Driveway

| Min. Order: | 5 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000ton/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Concrete Repaid Repair Materials, Concrete Driveway Crack Repair Materials, Best Concrete Waterproof Repair Mortar, Best Material For Filling Cracks In Concrete Driveway, Bridge Deck Expansion Joint Repair Solution |

Product Detail

| Model No.: | SC |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Huineng |

| Usage: | caulk and seal cracks in a concrete driveway |

| Color: | Grey |

| Initial setting time: | 25mins |

| Final setting time: | 35mins |

| Compressive strength: | 2h>30Mpa,1d >60Mpa |

| Pulling strength: | 2.8Mpa |

| Expansion rate: | 0.01% |

| Validation report: | MSDS |

| Certificate: | ISO9001 |

| Open to traffic: | Wthin 1 hour |

| Production Capacity: | 1000ton/month |

| Packing: | Paper plastic composite bag packaging, 25Kg/bag |

| Delivery Date: | Within 7 working days |

Product Description

How to Caulk and Seal Cracks in a Concrete Driveway

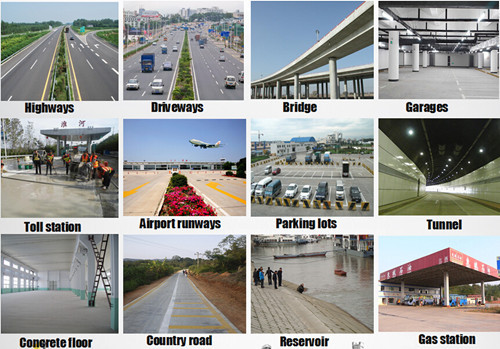

1.Applied range:

Highway,national road,provincial road,airport,municipal engineering and tunnel

Serious disease such as concrete plate fracture,serious crack,edge failure and pothole

2.Detail feature:

Achieved 1--2 h rapid open to traffic.

High compressive strength:2h>33Mpa,1d >60Mpa,meet requirement of rapid repair strength.

Good adhesion: Have super adhesion force with original concrete.

Good anti-crack property: Adapt to deformation of concrete base, and don't crack or fall off.

Good toughness: it is 5-8 times of normal concrete.

Expansion shrinkage coefficient is basically same with base course concrete.

Can be used in damp base course and damp environment as first-aid repair materials.

Simple and rapid construction.

3.Technical parameter:

Test items | Unit | Technical requirement | Test result | Individual conclusion | |

Setting time | Initial setting | Min | ≥20 | 25 | Meet requirement |

Final setting | ≤60 | 35 | |||

Compressive strength | 2h | Mpa | ≥20 | 33.0 | Meet requirement |

1d | ≥40 | 66.1 | |||

28d | ≥50 | 90.5 | |||

Pulling strength | 28d | Mpa | ≥2.0 | 2.8 | Meet requirement |

Expansion rate | 28d | / | 0.00%-0.1% | 0.01% | Meet requirement |

4.Quality control:

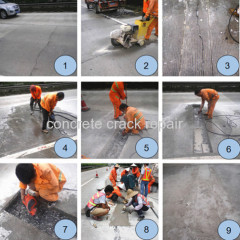

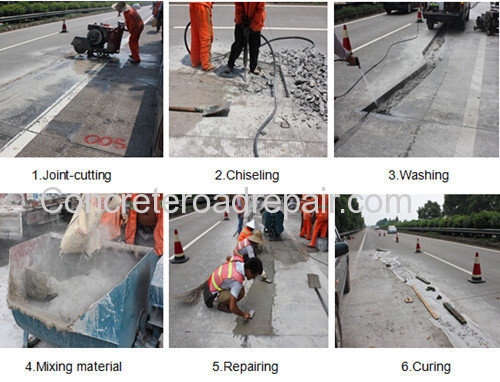

5.Construction process:

Joint-cutting

Chiseling

Washing

Mixing material

Repairing

Curing

6.Matters needing attention:

1)This repair material is of early type material, operation time is within 15 minutes, It can prolong

operation time as per user's request. Strictly prohibited use hardened mortar.

2)Add clean diameter ≤30㎜ continuous graded gravel aggregate,ratio is 50%.

3)In summer, Already repaired area surface should be prevented exposure.

The plastic film can be covered in repaired area surface.

4)It should pay attention to heat preservation and maintenance when winter.Can adopt hot water to stir, and cap rock wool quilt to keep warm. It can't construct when temperature below 5℃, wind power greater than 5 grade or rainy days.

7.Our service:

*Professional technology guide

*Search&Development as per your special requirement

*Stable production cycles

*On time delivery

*Completed quality control system

*24-hour online CALL service

*First-class after-sale service