electro permanent magnetic workholding

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 100pcs per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Magnetic Chuck |

Product Detail

| Model No.: | EPMC75 |

|---|---|

| Means of Transport: | Ocean, express, Air, Land |

| Processing Types: | Metal |

| Processing: | Milling Machine |

| Automatic Grade: | Others |

| Workpiece and Weight: | Large Machine Tool |

| Precision: | High Precision |

| Controlling Mode: | Others |

| Usage: | General |

| Brand Name: | SYF MAGNETICS |

| pole size: | 75X75mm |

| Nominal holding force: | 750 kgs per pole |

| pole number per square meter: | about 100 pcs |

| Used: | every size with medium thickness |

| other size and design: | on request |

| waterproof: | very good |

| improve use space: | with pole extension |

| for workpieces: | very good |

| use life: | very long |

| maintain costs: | no |

| Production Capacity: | 100pcs per month |

| Packing: | plywood |

| Delivery Date: | 15-25days |

Product Description

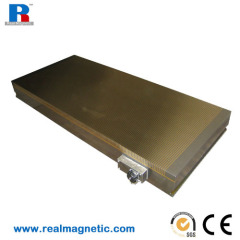

ELECTRO-PERMANENT MAGNETIC CHUCK

EPMC 75H Series

High polar density type, comprising size75X75mm poles with norminal holding force 750kgs each pole.

Ideal for every size with normal operating air gaps, also with medium thickness.

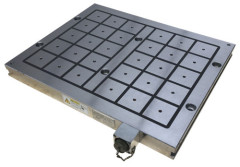

DESCRIPTION (electro permanent magnetic chuck) :

1 Comprising 50mm*50mm poles with a force of 380 kgf for each pole.

2 Each pair of N/S poles generates an autonomous and defined force which is not influenced by the operating conditions of the other adjacent poles.

3 It is possible to predetermine the force generated by counting the number of poles occupied by the clamped piece.

4 Optimum magnetic force is 4 alternate poles contact.

5 Operating with fixed and mobile pole extensions is better.

6 Equipped with longitudinal and transverse stop rails.

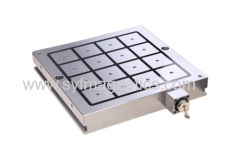

USE (electro permanent magnetic chuck):

7 Used for normal and heavy duty drilling, milling, and boring operations

8 Used for small, medium and large workpieces, including those with rough or uneven surfaces. Work pieces larger than the table surface are machinable. Min. thickness is 10mm.

FEATURES(electro permanent magnetic chuck):

9 5 sides machining

10 Easy and quick set-up

11 Drastic reduction in downtime

12 Uniform holding force over the work piece:no distortion

13 Reduced consumption of tools

14 No electric power supply during clamping

15 Simplified CNC or FMS programming