300*400 electro permanent magnetic workholding

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,DDP,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

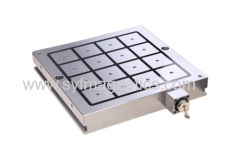

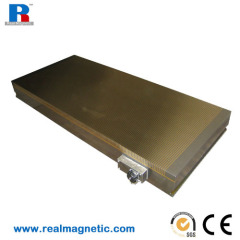

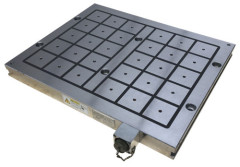

| Model No.: | EPM50H-304 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Processing Types: | Metal |

| Processing: | Grinding Machine |

| Automatic Grade: | Automatic |

| Workpiece and Weight: | Instrument Machine Tool |

| Precision: | High Precision |

| Controlling Mode: | CNC |

| Usage: | General |

| Brand Name: | Realmagnetic |

| Specification: | As your requests |

| Function: | Fix object |

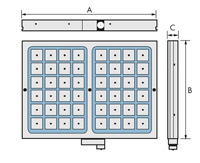

| pole size: | 50*50 mm |

| Export Area: | Global |

| pole number: | 20 pcs |

| Production Capacity: | 100 sets per month |

| Packing: | plywood |

| Delivery Date: | about 25 days |

Product Description

Flexibility | Cost-effectiveness | Safety | Productivity |

Selecting the right solution |

The standard series of Super-EPM chucks include more versions which have different performance characteristics. Capable of adapting to different operating needs, depending on the thickness. The surface condition (or the operating air gap) and the dimensions of the work piece to be clamped. The clamping force of each version depends on the different dimension types of poles and on the configurations of the magnetic area. |

| EPM50H |

| High polar density version comprising size 50 poles with a force of 380 kgf for each pole. Particularly suited to operating with fixed and mobile polar extensions, ideal for small and large pieces with normal operating air gaps, also with limited thicknesses.  |