Compressor rotor testing machine

| Place of Origin: | Shanghai |

|---|

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | WIND-RT-1 |

|---|

Product Description

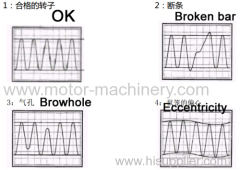

WIND-RT-1 rotor testing machine use high-precision sensor to detect rotor signals, operating simple and easy, judging defects of broken bar and thin bar automatically and then automatic alarm, the data can be stored and printed.

Test item:

Broken bars , too slim bars,

Porosity, sand holes,residues on bars,undercasing,

declination error,internal short circuit in bars

Alignment of core with bar

Improper end ring

Ask:

Why the waveform next to the AC induction motor diecast rotor broken bar of will become larger by tester?

Answer:

When cut magnetic lines, the broken bar of aluminum die casting Rotor doesn't produce induced current,

So for the next bar of cast-aluminum rotor, the current is abrupt.

When Browhole (Porosity) occur, the bar is thin or too slim,

Porosity and sand holes standard should be defined by user as they are common

Compressors motor rotor quality tester Technical Parameter:

Rotor Diameter | 30—130mm |

Rotor Length | 30—155mm |

Air pressure | 0.3MPa |

The Number of Conduction-bar | 10—100 |

Test Speed | 100—1500rpm |

Net Weight | Around 170KGS |

HS Code:9030390000

Skype: motor.machinery