Upgraded version high efficiency customized motor armature balancing equipment rotor testing machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-DH-6Z |

|---|---|

| Means of Transport: | Ocean, Air |

| Balancing rotation speed: | 2100 rpm |

| Weight of workpiece: | max 3Kg |

| Ambient temperature: | - 5℃~45℃ |

| OD of workpiece: | 20mm~80mm |

| Cycle time: | ≤10 second |

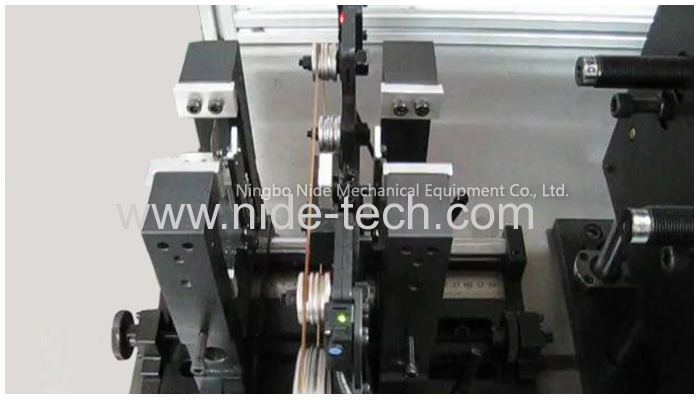

| Driving mode: | belt |

| Stack height: | 20mm-70mm |

| Pressure: | 0.4~0.6Mpa |

| Power supply: | AC220V±10% 50Hz |

| Maximum armature paramete: | 35 different armatures |

| Production Capacity: | 40 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 35 days |

Product Description

Upgraded version high efficiency customized motor Dynamic armature balancing equipment rotor testing machine

(1)Applications:

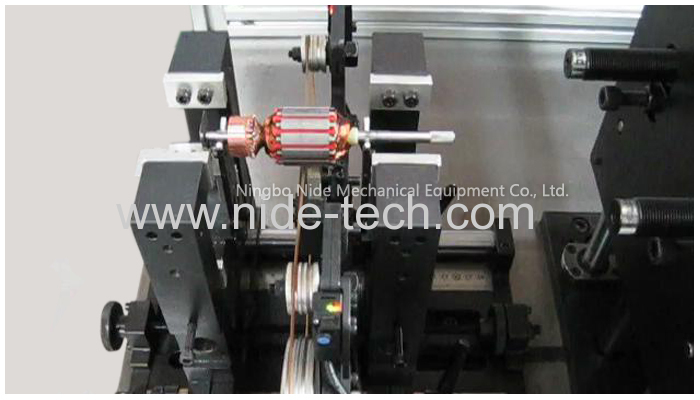

The armature rotor balancing equipment is used to measure the armature's unbalance. Man-machine interface can show the unbalance with its angle and value. The control system includes single chip, PLC and a man-machine interface.

The rotor balancing maching can measured Up to 35 different types of rotor

The rotor balancing machine is widely used in the motor field, such as wiper motor, vacuum cleaner motor, mixer motor, window lifter motor, condenser motor, power tool motor, DC motor, etc.

(2)Why armature balancing test

improve the quality of the rotor and its composition

reduce noise

reduce vibration

Extend the service life of bearing components (bearings)

reduce the user's discomfort, reduce product consumption.

(3) Machine function and characteristic

1.This armature balancing machine automatically measures the unbalancing amount of the armature, automatically stops the armature at the unbalancing position

2.Imbalance point positioning automatically

3.No need to mark on the armature (such as reflective sheet, black mark an so on)

4.Low operation skill requirement to staff

5.Reduce the complexity of the machine operation

6.Operator needs to stick the balancing mud onto the unbalancing position manually.

(4) Main technical data:

| Production name: | ND-DH-6Z Upgraded version dynamic armature balancing mahcine |

| Range of application: | Armature,Rotors |

| Armature diameter: | 20mm~80mm |

| Stack height: | 20mm-70mm |

| Ambient temperature: | - 5℃~45℃ |

| Humidity: | 83~95%RH(+40℃),68~74%RH(-15℃) |

| rotating speed: | 2100 rpm |

| Pressure: | 0.4~0.6Mpa |

| Cycle time: | ≤10 second |

| Power supply Uniphase phase: | AC220V±10% 50Hz |

| Maximum weight: | 3Kg |

| Maximum armature parameter: | 35 different armatures |

(5).Operating Ambient parameters

The armature balancing equipment can be used continually and normally in 72 hours under below condition when Ambient temperature is -5℃~45℃ and the Humidity is 83~95%RH(+40℃)or 68~74%RH(-15℃)

(6)The motor armature balancing equipment rotor testing machine adopts the following Main components

1.Touch panel(HMI): Proface 7" screen

2.PLC:KEYENCE

3.Step motor:Oriental Motor (≤1.5kg,Φ50mm)

4.Measuring station: 16.00

5.Machine body: 62.00

6.Vibration sensor: JZ-VSB2.0-80D

7.Testing machine main board: V1.0

8.Filter board: Analog board

Nide is a company devoted in the field of electric motors manufacturing, providing one-stop service for its customers. Nide has three main business divisions. The first division is to provide different kinds of motor manufacturing machinery, including stand along machine, fully-auto complete line for armature and stator production, and the motor assembly line,motor stator winding machine, staor insulation paper inserting mahcine, stator coil inserting machine , ,bldc / brushless motor winding machine,motor armature / rotor winding machine and rotor die casting machine,etc. The second division is to supply the full range of motor components such as commutator, ball bearing, carbon brush, insulation paper, shaft, magnet, fan, motor cover,etc. The third division is to provide technical support and consulting, project support and turn-key service for some motor manufacturing.