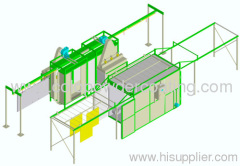

Aluminium profile powder coating production line

| Min. Order: | 1 Pound |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 5sets/year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | HICOLO |

| Production Capacity: | 5sets/year |

| Packing: | 40HQ container |

| Delivery Date: | 60days |

Product Description

Design basis of Aluminium profile Powder coating conveyorized line

Name of workpiece: Aluminium profile (Horizontal hangingmethod)

2. Max hanging size on each hanger:L6300mm×W200mm×H1500mm

3.Suggested interval between 2 hangers: 500mm

4.Conveying speed: 1.3m/min

5. Output: 10-12 hangers per hour

6. Sprayingmethod: 4 auto spray guns (match on 2 reciprocators) & 2 manual sprayguns

7. Heating source: natural gas (Other choices are available:electricity, oil or coal)

8. Required plant size:L52m×W24m×H6.5mm

Design description of automatic aluminium profile powdercoating line

1. According to the shape of aluminium profile, we designthe pretreatment to be economical immersion tank type with 6 stageprocessings.

2. After chemical cleaning, the pre-treated workpieces will beconveyed to drying furnace for water removal on their surface. The dryingfurnace is designed being tank type to match with immersion pretreatment tanks,and with a top-door design for easy access of pre-treated workpieces.

3.After drying, the workpieces are ready for powder particle adhesion. Pleasemanually feed them on auto powder painting line. For a better painting result,the spray booth, waster powder recycling system, reciprocator adopts advancedequipments in China through our careful selection. And the spraying guns, bothauto and manual are imported from foreign famous company for a longer servicelife. Then these workpieces will be sent to gas-fired furnace tunnel to letpowder melt into a smooth coating.

Process flow of Aluminium profile industrial coating line1. Feed your aluminium profiles on crane hanger for thepreparation for chemical cleaning

2.Pickling stage (Room temperature for 3-5mins)

3.Rinsing stage (Room temperature for 1-2 mins)

4.Rinsing stage(Room temperature for 1-2 mins)

5.Chromizing stage (25-35 Celsuis for 1-5mins)

6.Rinsing stage (Room temperature for 1-2 mins)

7.Rinsing stage(Room temperature for 1-2 mins)

8.Drying off oven to remove surface moisture(70-100 Celsuis for 20-30 mins)

9.Manually transfer the pre-treated objectsto powder coating line

10.Powder application with spray guns

11.Powdercuring (180-200 Celsuis for 20-18 mins)

12.Finished product discharging

Ifabove parameters cannot meet with your strict coating need, please contact usfor more detail. We can make some adjustments or even improvements to suit youractual production conditions.

Aluminium profile Turnkey Powder Coating Plant

Aluminium profile electrostatic coating line

Aluminium profile Complete Powder Coating Plant