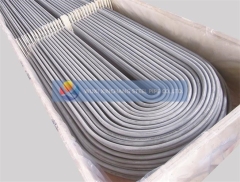

Heat exchanger stainless steel tube

1.0~5000.0 USD

| Min. Order: | 1 Metric Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 400ton/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | PLATE, VALVE, PIPE FITTINGS, STAINLESS STEEL PIPE |

Product Detail

| Model No.: | ASTM A213 |

|---|---|

| Means of Transport: | Ocean |

| stainless steel seamless pipe: | stainelss steel pipe |

| Production Capacity: | 400ton/month |

| Packing: | bundle packing by plastic strip |

| Delivery Date: | 30days |

Product Description

Heat exchangers are vital components in numerous process plants. With an increasing focus on operating economy and safety, the benefits achieved from baseline inspection and condition monitoring are evident.

MINGYUAN's heat exchanger tube provide a safety and economic way for clients focus on producing high-quality heat exchange products.

*Chemical Industry | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ASTM A213/ASME SA213 Seamless ferritic and austenitic alloy steels boiler superheater, and heat-exchanger tubes ASTM A249/ASME SA249 Welded austenitic steel boiler, superheater, heat-exchanger, and condenser tubes ASTM A268/ ASME SA268 Seamless and welded ferritic/martensitic stainless steel tubing for general service ASTM A688 Welded austenitic stainless steel feedwater heater tubes ASTM A789, ASME SA789 Seamless and welded ferritic/austenitic stainless steel tubing for general service ASTM A269, ASME SA269 Seamless and welded austenitic stainless steel tubing for general service ASTM A803 Welded ferritic stainless steel feed water heater tubes ASTM B163/ASME SB163 Seamless nickel and nickel alloy condenser and heat exchanger tubes ASTM B165/ASME SB165 Nickel copper alloy (UNS N04400)* seamless pipe and tube ASTM B167/ASME SB167 Nickel chromium iron alloys (UNS N06600, N06601, and N06690) seamless pipe and tubes ASTM B338/ASME SB338 Seamless and welded titanium and titanium alloy tubes for condensers and heat Exchangers ASTM B704/ASTM B705 Welded UNS N06625 and UNS N08825 alloy tubes / Nickel alloy (UNS N06625 AND N08825) welded pipe EN10216-5 Seamless steel tubes for pressure purposes - stainless steel tubes DIN 17175 Seamless tubes of heat-resistant steels - technical conditions of delivery DIN 17459 Seamless circular high-temperature austenitic steel tubes - technical delivery Conditions DIN 28179 Steel U-tubes for tubular heat exchangers - technical delivery conditions DIN 28180 Seamless steeltubes for tubular heat exchangers - dimensions, dimensional deviations and Materials DIN28181 Welded steel tubes for tubularheat exchangers - dimensions, dimensional deviations and Materials GOST 11017 Steel seamless tubes for high pressure service - technical conditions JIS G3455 Carbon steel pipes for high pressure service JIS G3462 Alloy steel boiler and heat-exchanger tubes JIS G3463 Stainless steel boiler and heat-exchanger tubes JIS H4631 Titanium pipes and tubes for ordinary piping | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| U-BENDING | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| U-BENDING U-TUBE HEAT EXCHANGERS COMPRISE A U-SHAPED TUBE FIXED BY FLOW BAFFLES OR TUBES SUPPORTS AND PLACED IN A SHELL TO CONTROL THE FLUID PRESENT IN THE EXTERIOR OF THE TUBE ASSEMBLY. THE FLUID IS GUIDED INTO THE TUBES BY A HEAD ASSEMBLY, WHICH IS FIXED TO THE SHELL BY BOLTS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bending Radius: From 1.5*od(outside diameter) to 1500mm When ordering tubes with bending radius less than 1.5*OD, it is necessary to get the agreement with seller Straight tubes maximum length(before bending): 35000 mm. Leg length: min 1 meter, max. 16500 mm (for max r=1500mm) Note: other size are available upon agreement. Heat treatment: stress relieved after u-bending (bending area plus 300mm for each leg). packaging: In strong transport-worthy pre-fumigated wooden boxes of corresponding dimensions for each tube length, radius, diameter, according to po requirements as well as wrapped in polyethylene films with soft plastic caps on both end of tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.100% PMI / SPECTRO CHEMICAL ANALYSIS TESTS 2.100% DIMENSION TESTS & 100% VISUAL EXAMINATION 3.TENSION TEST, FLANGE TESTS, HARDNESS TEST, REVERSED FLATTENING TEST 4.100% HYDROSTATIC TEST AFTER BENDING PLUS 100% NON-DESTRUCTIVE TESTS 5.CHECKING STRESS RELEASED HEAT TREATMENT IN BENDING AREA PLUS 300MM STRAIGHT LEG LENGTH AFTER BENDING WITH AGREEMENT WITH CLIENTS, SIGNING BENDING REPORT NOTES : ALL THE TESTS AND INSPECTION NEED TO PROVIDE WITH REPORTS ACCORDING TO STANDARD AND TEST RESULTS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.STRAIGHTNESS TEST 2.ROUGHNESS TEST 3.CRYSTALLING PHASE ANALYSIS 4.INTERGRANULAR ATTACK TESTS 5.IMPACT ATTACK TEST UNDER LOW TEMPERATURE 6 .U-BEND BALLING PASS TEST U 7.PT TEST ON BENDING AREA | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||