Plastic connector mold cavity insert process

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 20pcs 5days |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Mould Manufacturing, Precision Equipment Made Machining Part, Mould Base HASCO Mould Making, HDMI Connector Injection Mould Making, Grinding Parts For Connector Mold Parts Machining |

Product Detail

| Model No.: | XQ-083 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Xuquan |

| Name: | Mold cavity insert |

| Material: | SKD11 |

| QTY: | 20PCS |

| Accuracy: | 0.005mm |

| Surface by grinding: | 0.001mm |

| Clearance angle: | R0.03 |

| Parallelism: | 0.01 |

| Vaticality: | 0.01 |

| Surface treatment: | Polished |

| Process step: | Grinding,EDM |

| Production Capacity: | 20pcs 5days |

| Packing: | carton with bubble pad |

| Delivery Date: | 4days |

Product Description

Plastic connector mold cavity insert process

1, Base information

1.ODM &OEM |

2.Accuracy for grinding:0.001mm |

3.Accuracy for EDM:0.002mm |

4.Surface treatment:Ra0.04mm |

5.Parallelism:0.002mm |

6.Verticality:0.002mm |

7.Groove:0.002mm |

8.Clearance angle:R0.03mm |

9. Raw Material Brand: DAIDO.HITACHI (JAPAN).ASSAB (SWEDEN). |

2, Product process

Raw material

Milling for out size or Fast wire-cutting

Grinding for Groove or vertical angle etc.

Sodick EDM or Agia Charmillers process

Wire-cutting EDM

QC inspection

Packing

Shipment by air

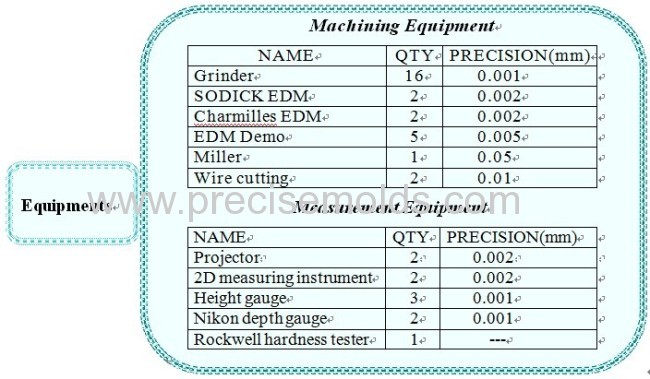

3, Advanced equipment

Device name | Quantity | Precision(mm) | Device name | Quantity | Precision(mm) |

Grinder | 16 | 0.001 | Projector | 1 | 0.002 |

Sodick EDM | 2 | 0.002 | 2D measuring instrument | 2 | 0.002 |

Agia chamillers EDM | 2 | 0.002 | Height gauge | 2 | 0.001 |

EDM fromTAIWAN | 5 | 0.005 | Nikon depth gauge | 2 | 0.001 |

Miller | 1 | 0.05 | Trimos electronic altimeter | 1 | 0.001 |

High-precision CNC | 2 | 0.005 | Rockwell hardness tester | 1 | --- |

Fast wire cutting | 2 | 0.05 | Punch grinder | 5 | 0.05 |

PIMM | 2 | Stamping machine | 2 |

4, Packing

Inner for vacuum packing with recycle plastic bag and anticorrosive oil; Outer for carton or wooden case, or according to customers' requirement.

5, Main market

1.Asia: 47.5% (Japan: SUMITOMO. KYOCERA,China: FCI.ITT.TYCO)

2.America: 27.5% (America: FCI. RCT)

3.Europe: 20% (France: C&K.TYCO.)

Other area: 5%

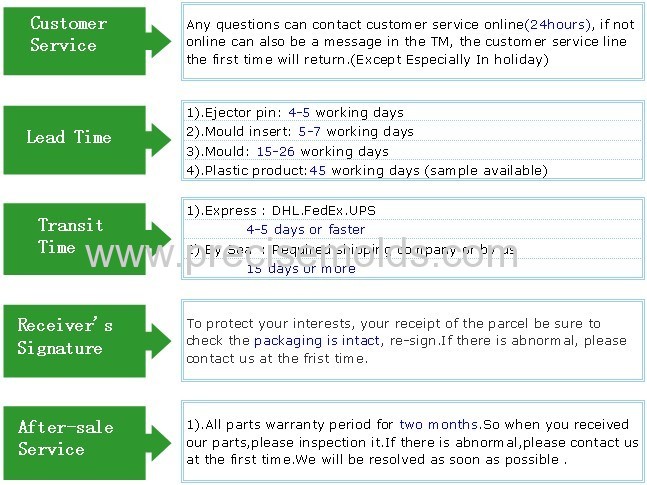

6, Service

Any inquiry will be replied by our professional staff within24hours,we will assist you in shipment, insurance and offering documents, such as TORM A,Embassy,certify,inspeciton certificate etc for clearance.

7, Good after sales service

Anything wrong happening in our products will be salved in 2 hours, we always offer relative technical support/consultant, quick response, all your inquiry will be replied within 24hours.

Company Mission We are committed to provide our best service to our customer for on time delivery, qualify product quality and competitive price to achieve mutual benefit. | + Quality Commitment We are committed to ensure all products and tooling delivers to our customer with zero defects and on time always. | |

+ Strength

| ||

8,Why choose us:

*- Specialize in precision mold and mold part ,your inquiries will get highly attention and be prompt response.(within 24 hours)

*- ISO 9001:2008 Certified, direct supplier, manufacture prices

*- Advanced facilities and experienced engineers, more than 6 years experience in mold part

*- Guaranteed quality, superior material quality compared to all other

*- Customer oriented, efficient solution to control the cost for our client

*- One-stop service, any questions can be solved at the first time by us

*- Each part has been got 100% test and tryout before shipment.