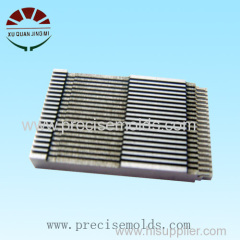

Plastic injection mould insert process

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 20pcs 4days |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Mould Manufacturing, Precision Equipment Made Machining Part, Mould Base HASCO Mould Making, HDMI Connector Injection Mould Making, Grinding Parts For Connector Mold Parts Machining |

Product Detail

| Model No.: | XQ-001 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Xuquan |

| Name: | Mould insert |

| Material: | SKD11 |

| QTY: | 20PCS |

| Accuracy: | 0.005mm |

| Surface by grinding: | 0.001mm |

| Clearance angle: | R0.03 |

| Vaticality: | 0.01 |

| Parallelism: | 0.01 |

| Process step: | Grinding,EDM |

| Surface treatment: | Polished |

| Production Capacity: | 20pcs 4days |

| Packing: | carton |

| Delivery Date: | 4 working days |

Product Description

High quality plastic injection mould insert maker

Not agency, not middleman, but direct supplier

to offer you our bottom prices.

1.About us:

XUQUAN--a prominent ISO 9001:2008 enterprise specialized in various of mould parts. Founded in 2008, which is located in the famous mould industrial zone Chang'an Town, China. Enjoying beautiful surroundings and convenient transportation.

It is more than 50 rich experience engineers and technical workers in our factory. Owning a large number of advanced precision manufacturing and measuring facilities, such as: 13 pieces Grinding machines, 9 pieces EDM machine (Sodick & Mitsubishi), 4 pieces milling machine,Wire cutting machines, Projectors, Altimeters and Microscopes,etc.

Most of the raw material come from Japan, Sweden and Germany, about 85% of our products are exported to Europe, America and Japan, both the output and the export are rising gradually year by year.

The products' precision can be made: size tolerance within 0.001mm, axiality within 0.002mm, roundness within 0.0015mm, surface roughness within Ra0.025, straightness within 0.002mm.

Trust us, your new direct supplier is here.

2. Products detail:

1.Raw materials are from Japan & Sweden, good compression strength and resists denting

2.Advanced manufacturing and measuring equipment(Sodick & Nikon), experienced engineering and technical workers with serious manufacture process.

3. strictly request of accuracy, it is our tenet to provide you the highest precision molds parts

4.Surface treatment can be nickel, galvanized and painted or as your special request

5.Quick delivery, small MOQ, Corrosion resistant and abrasion resistant, best after-sale service

3. Why choose us:

*- Specialize in precision mold and mold part ,your inquiries will get highly attention and be prompt response.(within 24 hours)

*- ISO 9001:2008 Certified, direct supplier, manufacture prices

*- Advanced facilities and experienced engineers, more than 6 years experience in mold part

*- Guaranteed quality, superior material quality compared to all other

*- Customer oriented, efficient solution to control the cost for our client

*- One-stop service, any questions can be solved at the first time by us

*- Each part has been got 100% test and tryout before shipment

XUQUAN Precision Mold Co.,Limited is a manufacturing factory located in China Suzhou, we are specialist in precision mold making, Custom make mold insert, plastic injection molding for connector, Gear, Optical product , electrical product etc...

We have a experience rich team members in each section to ensure each stage are well organized and keep schedule in line with planned schedule.

There are some interesting mold and product in very miniture size and high flexiability during production that can help to reduce cost and increase productivity.

Please spend some time on review our website and we are welcome your enquiry anytime around the year.

Company Mission We are comitted to provide our best service to our customer for on time delivery , qualify product quality and competitive price to achieve mutual benifit. | + Quality Comittment We are comitted to ensure all product and tooling deliver to our customer with zero defect and on time always. | |

+ Strength

| ||