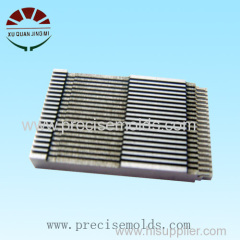

Connector plastic injection mould insert

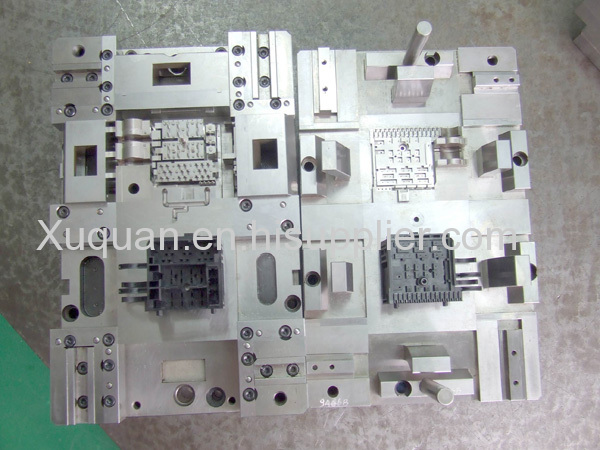

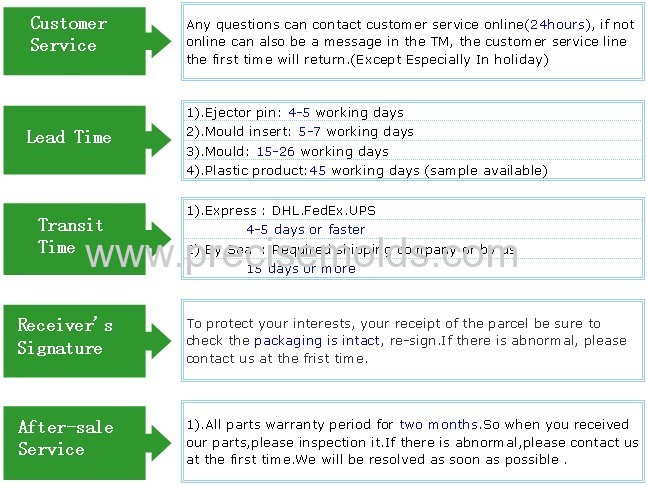

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T, WU |

| Supply Ability: | 20pcs 4days |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Mould Manufacturing, Precision Equipment Made Machining Part, Mould Base HASCO Mould Making, HDMI Connector Injection Mould Making, Grinding Parts For Connector Mold Parts Machining |

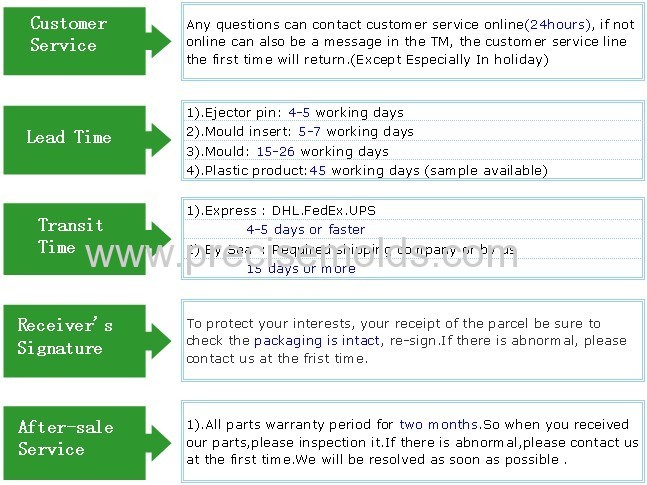

Product Detail

| Model No.: | XQ-011 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Xuquan |

| Name: | Connector plastic injection mould insert |

| Material: | SKD11 |

| QTY: | 20PCS |

| Surface by grinding: | 0.001mm |

| Clearance angle: | R0.03 |

| Vaticality: | 0.01 |

| Parallelism: | 0.01 |

| Surface treatment: | Polished |

| Process step: | Grinding,EDM |

| Lead time: | 4 working days |

| Production Capacity: | 20pcs 4days |

| Packing: | carton |

| Delivery Date: | 4 working days |

Product Description

Connector plastic injection mould inserts

1.Feature :

1) Design: We use the most advanced mould design software AutoCAD, UG.

2) Manufacture: We use With advanced technology, unmatched skill, professional equipment, and experienced technicians to fit our customers requirements.

3) Mould base: LKM Brand, HASCO and so on

4) Cavity/core material: DIN1.2344, 738H, 718, 8407, S136, NAK80,P20, SKD-61, NIMAX etc

5) Cavity Qty: Single/ Multi-cavity.

6) Lead time: 25-50days based on the different products

7) Warranty: 500,000-1,000,000shots as per customers' requirement

8) Products material: PP, PA, POM, ABS, PET, PC, PE,HDPE, PA66+GF,PVC, TPE,etc

9) Hot Runner: HASCO, YUDO, DME, MOLD-MASTER

10) Color Standard: Pantone, Ral

11) Texture: VDI, YS

12) Price Terms: FOB,China

13) Packaging: Wood case or as per customers' requirement

14) ISO9001:2000 Certificate

2.Molded Plastic Products

XUQUAN Mould Co., Ltd | ||

1 | Mould Base Standard : | LKM Brand, Hasco, DME ect ; |

2 | Cavity/Core Material : | 2738,2343,DIN-1,S130, 2344,738H,718,8407,S136,NAK80,P20,KD-61,NIMAX ect ; |

3 | Hardness of the steel : | 20-60HRC ; |

4 | Cavity Qty : | Single-cavity / Multi-cavity ; |

5 | Runner : | Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER Hot runner or Cold runner ; |

6 | Gate : | Submarine gate, side/edge gate, direct gate ect ; |

7 | Plastic Part Materials: | PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPE etc ; |

8 | Mould Life Time : | 500,000-1,000,000shots as per customers' requirement ; |

9 | Quality : | ISO9001:2000 Certificate ; |

10 | Lead Time : | 25-45 workdays based on the different products ; |

11 | Package : | Wooden Case Package or As per Customers' Requirement ; |

12 | Price Terms : | FOB ,China; |

13 | Payment term: | T/T, L/C at sight; |

14 | 8 Years Professional Manufacture Experience, Specialize indesign and the manufacture of Plastic Injection Mould and tooling for Automotive, Electronic equipment,Medical Products, Double Color part and other. | |

15 | OEM & ODM orders are welcome. | |