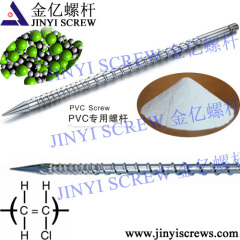

chromium plating barrier screw barrel for PVC

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 2000 Sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Brand Name: | HUACHEN |

| Material: | 38CrMoAlA,SACM645,42CrMo |

| Treatment: | Nitriding and bimetallic |

| Bimetallic layer: | add 5%-45% Tungsten Carbide |

| Apply for: | PVC PE PP... ,PVC+GF,ABS,etc |

| Machine: | injection molding machines |

| Final product: | Profile,sheet,board,pelletzing,etc. |

| Machine Brand: | Haitian, Demag, Engle,CHINA BRANDS,etc. |

| Technology: | CNC Machines |

| Specification: | Φ15-Φ405 |

| Packing: | AA grade worden Case |

| Production Capacity: | 2000 Sets |

| Packing: | Worden Case |

| Delivery Date: | 25-30 days |

Product Description

HUACHEN SCREW Purpose:

To creat china famous brand,to build first-classenterprise!

Create the greatest value for ourcustomers!

Screwdiameter:Φ15mm-Φ220mm

Mould clampingforce:25-38000KN Injection capacity:30-50000g

Screw can be designed according to different plastic material and final products

As per customers' demand,we can supply below:

1:PMMA Screw,Bakelite Screw,PVC Screw,PA Nylon+GF Screw,PC Screw

2:All kinds of accessories, screw tip, non-return valve,check ring,nozzle,end cap

Feature of our screw barrrel:

wear-resistance corrosion- resistance, high temperature resistance, highpressure resistance

--NormalMaterial we use asfollowing:

1.38CrMoAlA(JISSACM645),

2.Cr12MOV(JISSKD-11)

3.4Cr5MoSiV1(JIS SKD-61)

4.42CrMo(AISI4140)

--The foreign material we usedasfollowing:

1. Germanysteel, GH113 ,2250,2842,1.8509 ,1.442 ,1.6582 ,1.6523 ,1.2080,1.4542,

2. USAsteel,P20,420,L6,H13,W110,D3,A2,D6,O1,S1,M35,8620,3115,K52440

3. Swedensteel,718S,718H,S136,S136H,STAVAX,ASP-23,ASP-30

4. AustraliaSteel,M202,M300,W302,K460,W300,K900,K100,W321

5. Hardnesssteel, YG6X,YG6A,YG6,YG8N,YG8,YG8C,YG11C,YG 15,YT5,YT14,YT30

6. Japan Steel, SKT 4,YXM4,YXM42,SNC 815,SK -3,SKS 3,and etc.

TechnicalParameters:

sheet 1

| Base Materials | 1)38CrMoAlA(JIS SACM645) 2)Cr12MOV(JIS SKD-11) |

| Bimetallic | 1)Fe-based alloy 2)Ni-based alloy |

| Tungsten Carbide | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containingtungstenof9.5% |

Sheet 2

| Plstic material application | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(inScraporGranule),etc |

Sheet 3

Heat Treatment | High Frequency Treatment |

Nitriding treatment(120 Hours) | Depth of Nitrided Layer: 0.5-0.8 mm Hardness of NitridedLayer:900-1020Hv(HRC56°-65°) |

Hard Chrome Plating treatment | Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: ≥950HV |

| Bimetallic treatment | BimetallicBarrel/Cylinder: Centrifugal Casting(InlayAlloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness ofBimetallicLayer:HRC55°-72° |

sheet4

| Roughness of the surface | Ra0.4um |

| Linearity of the screw | ≤0.015mm |

| Linear axis limit | ≤0.02mm |

| Hardness after Hardening & Tempering | HB240-280 |

| Fragility of Nitration | ≤Two class |

Besides nitrided screw barrel, we also provide bimetallic screw barrel,chromium plating screw barrel,WC coating screw barrel.titanize plating screw barrel and etc.

Sample: