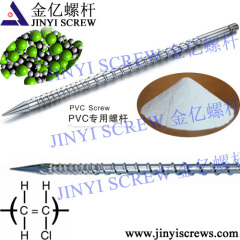

Injection screw barrel for PVC

800.0~1500.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500sets/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Screw Barrel, Extrude Single Screw, Parallel Twin Barrel |

Product Detail

| Model No.: | ISC-90 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Vanscrew |

| Marerial: | 38CrMoALA |

| Heat-treatment: | Nitrided |

| Nitrided depth: | 0.5-0.8mm |

| Hardness: | Hv900-1000 |

| Ratio of length to diameter: | 25 |

| Production Capacity: | 500sets/Month |

| Packing: | wooden case |

| Delivery Date: | 30days |

Product Description

Product Material:

1. 38CrMoALA(JIS SACM645)

2. 42CrMo (JIS SCM440)

3. 9Cr18MoV

4. CW6Mo5Cr4V2

5. Various high quality alloy steels, According to different usage, the choice for alloy is different, types of steel depending on customer requirement.

Technological Process for rubber screw barrel

Blanking→Rough Machining→Quenching & Tempering →Semi Finishing Machining→Finished Product→Detecting→Nitring/Alloy Processed →Finish Machining

Technologic Guidance:

| Material | 38CrMoALA,9Cr18MoV |

| Application | PVC,ABS,TPO |

| Hardness After Hardening &Tempering: | HB240 -280 |

| Nitrided Hardness: | Hv850-1000 |

| Nitrided Depth: | 0.45-0.7mm |

| Nitrided Brittleness: | ≤Grade 2 |

| Surface Roughness: | Ra0.4 |

| Screw straightness: | 0.015mm |

| Surface Chromate-plating's Hardness After Nitrided: | ≥900Hv |

| Chromate-plating Depth: | 0.05-0.10mm |

| Bimetallic-alloy Hardness: | HRC56 -65 |

| Alloy Depth: | 0.8-2.0mm |