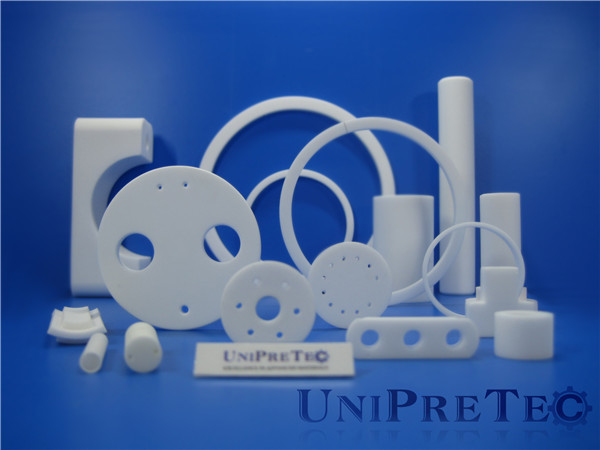

Alumina Ceramic Insulator Ring

| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 2000 pieces/month |

| Place of Origin: | Fujian |

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Boron Nitride, Boron Carbide, Silicon Nitride, Slicon Carbide, Zirconia Ceramics |

Product Detail

| Model No.: | customized |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | UNIPRETEC |

| Material: | Alumina |

| Density: | 3.65 - 3.95 g/cm3 |

| Color: | White, Ivory |

| Max. Working Temp.: | 1500 - 1700 C |

| Compressive Strength: | 2200 - 2500 Mpa |

| Flexural Strength: | 280 - 350 Mpa |

| Water Absorption: | 0% |

| Thermal Conductivity: | 20 - 30 W/m.k |

| Crystal Structure: | Hexagonal |

| Young's Modulus: | 280 - 350 Gpa |

| Production Capacity: | 2000 pieces/month |

| Packing: | carton box with foam |

| Delivery Date: | 30 days |

Product Description

Alumina ceramic is the most mature of the engineering ceramics, offering excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness.Alumina Ceramics are generally white but may also be pink (88% alumina), or brown (96% Alumina). The colour is derived from either the sintering additives or impurities in the raw materials. UNIPRETEC produces a range of high purity alumina ceramics in the range of 92% – 99% purity.

92% Al2O3

Has very good electrical and mechanical properties and is metallized easily. The black body is used primarily for lids and when metallized and plated with gold has a very distinct appearance.

94% Al2O3

Possess very good electric and mechanical properties and is very easily metallized with the MoMn process.

96% Al2O3

This is our standard body and it has been formulized to meet with good success with just about anyone's MoMn process. This body still possesses the same good mechanical and electric properties as the previous two alumina bodies.

99% Al2O3

This body is used extensively in the medical industry. Its finer grain allows it to be polished to achieve fine micron finishes making it the material of choice for pump manufacturers and it is used for wire/thread guides as well as for mechanical seals. Though it can be metallized it normally does not lend itself to that process due to its lack of glassy phase.

High purity alumina ceramics are ideal for environments where resistance to wear and corrosive substances are required. Alumina ceramic has excellent thermal stability, which means that it is widely used in areas where resistance to high temperatures is essential.

Alumina ceramic is the material of choice for alumina wear parts. The proven wear and heat resistance of alumina wear parts makes them ideal for the manufacture of wear-resistant components.

Alumina has a high melting point, high hardness,although mechanical strength is reduced at temperatures above 1000 C. Due to the relatively large coefficient of thermal expansion, thermal shock resistance is reduced.

Alumina is an electrically insulating material, with a high electrical resistivity, increasing with purity.

Good chemical stability of alumina leads to high corrosion resistance. It is insoluble in water and only slightly soluble in strong acid and alkaline solutions. Testing has shown that the low chemical solubility of alumina ceramics components makes them highly resistant to chemical corrosion. This is what makes high purity alumina the material of choice for components in a wide range of industrial applications.

All alumina bodies possess very good mechanical properties such as hardness and compressive strength. They also hold up well under harsh conditions such as acid corrosion, high wear areas, and sliding abrasion. They also possess very good electrical insulation properties and have very specific thermal conductive and thermal expansion rates.