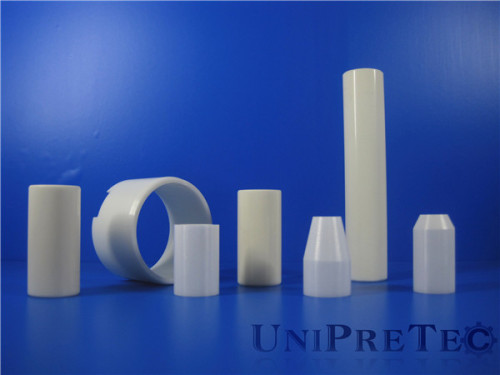

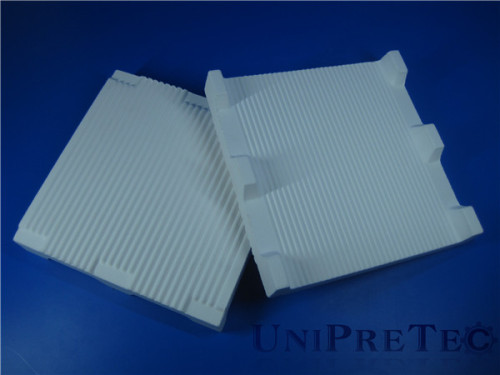

Tube Rod Plate Ring Bushing Sle eve Ceramic Insulator

| Min. Order: | 50 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 65000pcs/year |

| Place of Origin: | Fujian |

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Industrial Ceramic, Advanced Ceramic, Technical Ceramic |

Product Detail

| Model No.: | UPT-ADC008 |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | UNIPRETEC |

| Material: | Alumina, Zirconia, Boron Nitride |

| Color: | White, Ivory, Gray |

| Density: | 2.26-5.95g/cm3 |

| Young's Modulus: | 205-670Gpa |

| Flexural Strength: | 51-900Mpa |

| Compressive Strength: | 230-2500Mpa |

| Thermal Conductivity: | 2.2-30W/(m•K) |

| Thermal shock resistance: | 180-1500ΔT(℃) |

| Max. Working Temperature: | 850-1700℃ |

| Production Capacity: | 65000pcs/year |

| Packing: | wooden box/carton box |

| Delivery Date: | 40days |

Product Description

Advanced ceramics is different from traditional ceramics.Traditional ceramics include clay products, silicate glass and cement,but advanced ceramics are ceramic products made from materials like aluminum oxide (Al2O3), zirconium oxide(ZrO2), silicon carbide(SiC), silicon nitride(Si3N4), boron carbide(B4C) etc. In general, this kind of ceramic products have the following properties:

*Hard (wear resistant)

*Resistant to plastic deformation

*Resistant to high temperatures

*Good corrosion resistance

*Low thermal conductivity

*Low electrical conductivity

Additionally, some ceramics exhibit other properties like high thermal conductivity or high electrical conductivity etc. The combination of these properties means that ceramics can provide:

*High wear resistance with low density

*Wear resistance in corrosive environments

*Corrosion resistance at high temperatures

Because of these special properties,the application of advanced ceramic is very wide.For example:

1.Seal rings

2.Medical prostheses

3.Laser tubes

4.Electronic substrates

5.Ballistic armour

6.Thermocouple tubes

7.Electrical insulators

8.Grinding media

9.Threadguides

10.Wear components

| Characteristics | Unit | 95 Al2O3 | 99 Al2O3 | ZrO2 | GPSi3N4 | BN | Glass Ceramic |

| Crystal Structure | - | hexagonal | hexagonal | tetragonal | hexagonal | hexagonal | - |

| Color | - | white | ivory | white | gray | white | white |

| Density | g/cm3 | 3.65 | 3.88 | 5.95 | 3.22 | 2.26 | 2.55 |

| Water Absorption | % | 0 | 0 | 0 | 0 | 0.0-1.0 | 0 |

| Young's Modulus | Gpa | 280 | 350 | 205 | 295 | 670 | 65 |

| Vickers Hardness | Gpa | 14 | 20 | 12 | 18-20 | - | - |

| Flexural Strength @R.T. | Mpa | 280 | 300 | 900 | 650 | 51 | 100 |

| Compressive Strength @R.T. | Mpa | 2000 | 2500 | 2200 | 2200 | 230 | 500 |

| Thermal Conductivity @R.T. | W/(m*k) | 18-25 | 30 | 2.2 | 25 | 20 | 1.7 |

| Thermal shock resistance | Δ(℃) | 220 | 180-200 | 280-350 | 450-650 | >1500 | 25-100 |

| Max. Working Temperature @R.T. | ℃ | 1500 | 1700 | 850 | 1200 | 960 | 800 |

| Volume Resistivity @R.T. | Ω*cm | >10^15 | >10^14 | >10^12 | >10^14 | 10^13 | 10^16 |

| Dielectric Constant (1 MHz @R.T. ) | - | 9.5 | 9.8 | 26 | 8.2 | 4.08 | 6.02 |

| Dielectric Strength | kV/mm | 16 | 22 | - | 16 | 375 | 40 |

UniPreTec provides high-performance ceramic products in Alumina, Zirconia, Boron Nitride, Machinable Glass Ceramic, Silicon Nitride and further special materials. Along with these materials, we offer several machining from which to choose such as cutting, drilling, sawing, turning, grinding, polishing etc.. Furthermore, our technologies and equipments allow us to provide various and flexible forming processes, like dry pressing, isostatic pressing, extrusion, injection moulding and slip casting.