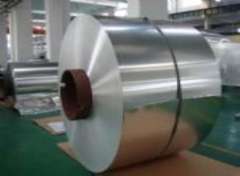

China Stainless steel coil

10000.0~11000.0 USD

| Min. Order: | 3 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 10000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

| Main Products: | Stainless Steel Banding Band |

Product Detail

| Model No.: | 7219340000 |

|---|---|

| Means of Transport: | Land |

| Stainless steel strip: | Stainless steel coil |

| Production Capacity: | 10000 |

| Packing: | carton package standard export package |

| Delivery Date: | 15-30days |

Product Description

Dust

Production is often in the dust site, a lot of dust with air, they keep falling on the surface of equipment. They can be removed with water or alkaline solution. However, there is adhesion dirt need high pressure water or steam cleaning

.Floating dust or embedded iron

.Floating dust or embedded iron

On any surface, free iron will rust and corrosion of stainless steel. Therefore, must clear. Floating powder can be removed with the dust. Some adhesion strong, must according to the iron treatment of embedded. In addition to dust, many sources of surface iron, including ordinary carbon steel wire brush to clean up and previously used in carbon steel, low alloy steel or cast iron used sand, glass beads or other abrasive for shot peening, or referred to in front of in the vicinity of stainless steel parts and equipment of non stainless steel products for grinding. When the material or hanging over the process if not stainless steel to take protective measures, wire rope, sling and the work table of iron is easy to embed or polluted surface.