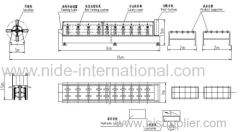

STEEL SILO ROLL FORMING MACHINE

| Place of Origin: | Jiangsu |

|---|

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Purlin Forming Machine, Roll Forming Machine, Downspout Machine, PU Sandwich Panel Product Line, Slitting Line And Cut |

Product Detail

| Power: | Hydraulic |

|---|---|

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Coiling Bending Machine |

| Extra Services: | Cut To Length |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Delivery Date: | 60 |

Product Description

steel silo roll forming machine ,steel silo ,roll forming machine ,roller machine

Glazed tile, Roof Tile, Metal roof tile; steel roof tile; color steel tile; color glazed tile; wave tile; steel roofing sheet; metal roof panel; steel roof panel; roof wall cladding; roof cladding; wall cladding A). Main Specification:

B). Main Components: C). Work Flowing:

Competitive Advantage: |

| Product Tags: Glazed Tile Roll Forming Machine Glazed Tile Roll Forming Machine Glazed Tile Roll Forming Machine |