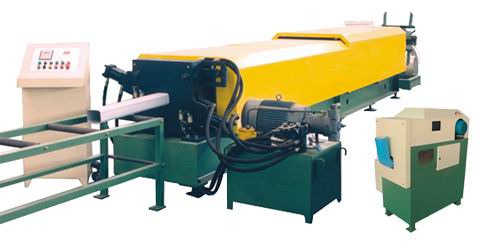

Downpipe roll forming machine

| Min. Order: | 1 pcs |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

| Main Products: | Carbon Brush For Motor, Insulation Paper For Motor, Small Size Deep Groove Ball Bearings, Commutator\ Komutator\ Kolektor For Motor, High-speed Plastic Friction Washer Machine |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Power: | Others |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Coiling Bending Machine |

| Automation: | Automatic |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Nide |

| raw material thickness: | ≤0.55 |

| raw material width: | ≤500mm |

| line speed: | 15m/min |

| rolls material: | NO.45 steel with hard chrome plating surface |

| drive mode: | external chain drive |

| electronic control system: | industrial PC, PLC and inverter control |

| console way: | By touching screen + button |

| Main power: | 3.5kw |

| Hydraulic power: | 5.5kw |

Product Description

Downpipe machine is composed of open systems, feeding guidance system, roll forming, cutting systems, finished

products supporting material, and automatic control system of hydraulic systems and other components..The device's products are widely used in steel structure buildings, villas, such as a sewer pipe.

technological process

roll froming - cutting -table for finish product

Main Component structure characteristics and description

★ roll forming system

1.Roll forming system is composed of steel frame, transmission components and cold forming roller section and so

on.

2.rollers materials is 45th steel , through forging, precision CNC machining, surface plating Hard chrome polished.

3.roll axle with 45 steel after quenching and tempering process, the support structure is wall plate

4.cycloid reducer, lower rollers rotate the wheel group by chain - driven, part of the upper and lower rollers used gear drive.

5. by manually screw adjusted up and down roller gap to accommodate rolled plates with different thickness. tolerance of the Production will vary by different strength and thickness of the substrate.

★ hydraulic cutting system

Cut off the system by cutting off the rack, Cutter mold, guiding device and cut off the fuel tank and so on.

1 ) Cut off the rack using welded frame, rigid well as a whole.

2 ) cutting mould matches the section of the sheet, effectively reduce the deformation of the cutting Department ; the use of bi - directional cutting helical cutting ways to cut up or down, no waste produced ; cutter material for cr12 hardening treatment

3 ) the steering device using the slider structure, making the knife plate under the stress of a smooth to cut sheet.

4 ) cut the power provided by a host of hydraulic station,

hydraulic motor power : 5.5kw

★ Electronic control PLC

1 ) use of PLC Control Technology, frequency adjusting speed technology to achieve full automatic production.

2 ) system provides a interface, you can set the number of batches, the length of the workpiece, and so on.

3 ) Operation : touch screen + button.

4 ) Encoder counts, with the count and length counting function.

5 ) use Mitsubishi PLC.

★ Hydraulic system

1 ) use an external independent hydraulic station ( provide power for cut off ).

2 ) the main valve Adopts famous brand.