High Quality Polystyrene Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets one month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | EPS Machinery, Plastic Machinery, Foma Machine, Cutting Machine, Block Moulding Machine |

Product Detail

| Model No.: | FDS1100B(1)-5 |

|---|---|

| Means of Transport: | Ocean, Land |

| Plastic Type: | Others |

| Use: | Others |

| Shaft Design: | Others |

| Brand Name: | DONGSHAN |

| Weight: | 5800kg |

| Capacity: | 7g/l 450kg/h |

| Usable Volume: | 3.5m3 |

| Consumption: | 0.7-1.0m 3 /cycle |

| Pressure: | 0.4-0.8Mpa |

| Material Conveying Line: | DN150*2 |

| Entry: | DN50 |

| Expanded Density: | 4.5-50kg/m 3 |

| Density Tolerance: | <=2.8% |

| Overall Mimension: | 9000*3500*5500(mm) |

| Production Capacity: | 10 sets one month |

| Packing: | bare |

| Delivery Date: | 30 days |

Product Description

High QualityPolystyrene Machine

Polystyrene Machine for expanding foam

Hangzhou Fuyang Dongshan Plastic Machinery Co.,Ltd. is a professional EPS machinery manufacturer integrating R&D, production, sales and service. The company has been rapidly developing into one of the biggest and most competitive corporation in EPS machinery industry after years of efforts.

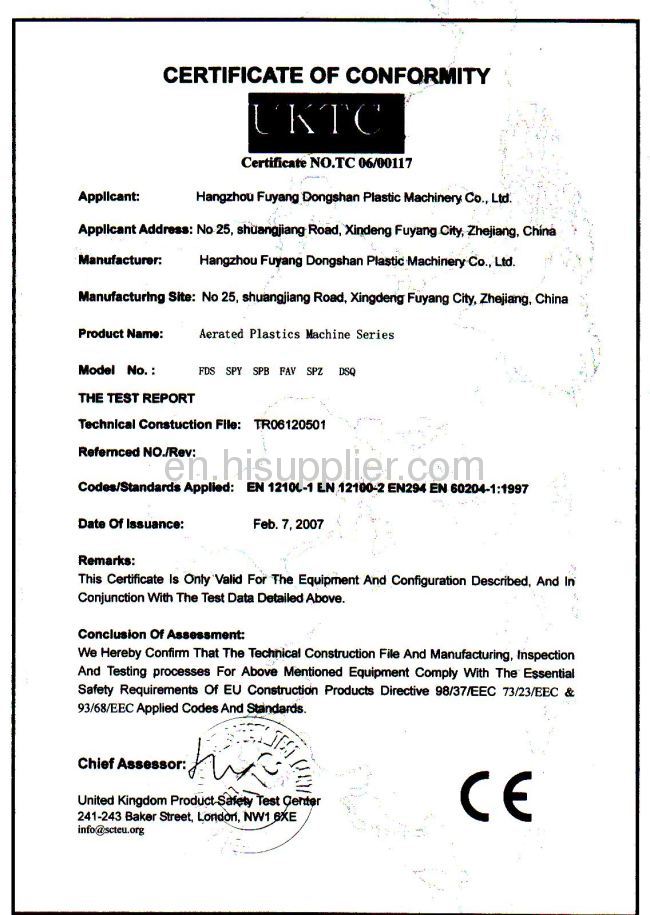

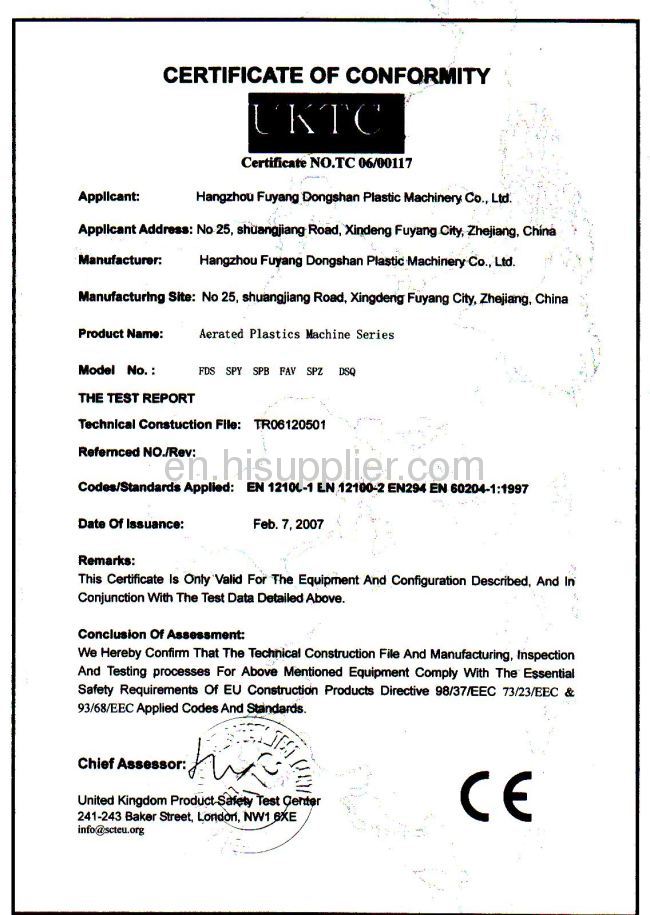

Dongshan company focuses on the quality and technological innovation of the machinery. With the dedicated technical force and accurate manufacturing ability, the company can now produce a wide range of EPS machinery to meet different requirements of clients. The technique, quality and practical values of DONGSHAN MACHINERY are leading in domestic EPS industry, particularly The series of Block Moulding Machine and Pre-expander Machine, which are better compared with the advanced machinery in developed countries, some technology and technique lead in top level, it is one of the best EPS machinery in the world. The company carries out scientific management, and all production procedures are under strict supervision and subjected to rigorous inspection, we successively passed ISO9001: 2000 quality management system authentication and CE authentication, providing a solid guarantee for product quality.

DONGSHAN machinery are highly appreciated and so popular at home and abroad. Nowadays, the marketing net extends all over the world, the company has become one of the biggest EPS machinery supplier in China and the products sold in more than fifty countries around the world, especially our Auto Block Moulding Machiney is all well known and shares one of the biggest market in China.

Hangzhou Fuyang Dongshan Plastic Machinery Co.,Ltd locates in the center of Yangtze River delta---Hangzhou city, which is deveoping at the fastest speed and most developed economy area in China, closes to the main ports such as Shanghai and Ningbo, it is very convenient for the transportation and shippment.

Dongshan company follows the concept of " quality first, market-oriented, growth based on credit". While focusing on innovation and modern management, the company always puts the clients' interest on the first place, and offers clients top products and considerate service all the time!

Warmly welcome the clients and friends from all over the world to visit our company!

Polystyrene Machine for expanding foam

Characteristics:

- This machine applies PLC and touch screen,automatic feeding,electronic weighing,temperature control,material level control to realize automatic production.

- Electronic weighing system and material level control system assure the density of the foamed material, which make the bead uniform and keep the density tolerance within±2.5%.

- High precise guiding pressure reducing valve controls the temperature and steam pressure of the closed barrel, ensure the outcome pressure of the valve constant and the inner temperature controled within ±1%℃,which keeps the foamed material equal and prevents the bead agglomerate because of the bad temperature control.

- Automatic material charging system improves efficiency and reduces labor intensity.

- The closed constant pressure foaming barrel has high heating efficiency. It can save more than 50% energy compared to the continuous pre-expander.

- Hot air drying system to dry the foamed material inside the barrel without fluidized drying bed.

- Automatic discharging from the pre-extender,which can automatically filter, crush the ball material and transport the foamed material to aging silos.

- Most of the main component are of world-famous brand,with reliable performance,stable quality,long service life and low maintenance cost.

- This machine applies automatic discharging system,the high pressure fan facility improves the speed of discharge.

- The computer has memory function, which can record all information such as brands, specifications, expanding foam techniques and parameters of EPS material manufacturers. When customers want to use the materials that ever been used before just press the touch screen of computer to quickly go back to the original technique.

- This machine is applicable in plateau oxygen depletion area,the production efficiency of continuous pre-expander machine is quite low under such circumstance.

Technical data ITEM FDS1100B Expansion Chamber Diameter DN110 Volume 1.4m 3 Usable Volume 1.0m 3 Steam Entry DN50 Consumption 6-8kg/cycle Pressure 0.6-0.8Mpa Compressed Air Entry DN25 Consumption 0.9-1.1m 3 /cycle Pressure 0.5-0.8Mpa Drainage Upper Drain Port DN100 Down Drain Port DN100 Down Vent DN80 Material Conveying Line DN150 Capacity 10.5g/l 320kg/h 15g/l 550kg/h 20g/l 750kg/h 30g/l 850kg/h Connected Load/Power 19.5KW Expanded Density 10-45kg/m 3 Density Tolerance <=2.5% Overall Mimension 2900*4500*5900(mm) Weight 3700kg

certification.

Hangzhou Fuyang Dongshan Plastic Machinery Co.,Ltd. is a professional EPS machinery manufacturer integrating R&D, production, sales and service. The company has been rapidly developing into one of the biggest and most competitive corporation in EPS machinery industry after years of efforts.

Dongshan company focuses on the quality and technological innovation of the machinery. With the dedicated technical force and accurate manufacturing ability, the company can now produce a wide range of EPS machinery to meet different requirements of clients. The technique, quality and practical values of DONGSHAN MACHINERY are leading in domestic EPS industry, particularly The series of Block Moulding Machine and Pre-expander Machine, which are better compared with the advanced machinery in developed countries, some technology and technique lead in top level, it is one of the best EPS machinery in the world. The company carries out scientific management, and all production procedures are under strict supervision and subjected to rigorous inspection, we successively passed ISO9001: 2000 quality management system authentication and CE authentication, providing a solid guarantee for product quality.

DONGSHAN machinery are highly appreciated and so popular at home and abroad. Nowadays, the marketing net extends all over the world, the company has become one of the biggest EPS machinery supplier in China and the products sold in more than fifty countries around the world, especially our Auto Block Moulding Machiney is all well known and shares one of the biggest market in China.

Hangzhou Fuyang Dongshan Plastic Machinery Co.,Ltd locates in the center of Yangtze River delta---Hangzhou city, which is deveoping at the fastest speed and most developed economy area in China, closes to the main ports such as Shanghai and Ningbo, it is very convenient for the transportation and shippment.

Dongshan company follows the concept of " quality first, market-oriented, growth based on credit". While focusing on innovation and modern management, the company always puts the clients' interest on the first place, and offers clients top products and considerate service all the time!

Warmly welcome the clients and friends from all over the world to visit our company!

Keep leading in China, create the well-known brand around the world;

Dongshan people, who have been insisting on devotion, cooperation and innovation, march forward and create new wonder in the past, present and future!

Dongshan people, who have been insisting on devotion, cooperation and innovation, march forward and create new wonder in the past, present and future!