high quality eps expanded polystyrene machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Shandong |

Company Profile

| Location: | Yantai, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | EPS Machine |

Product Detail

| Model No.: | psj-500-1400 |

|---|---|

| Plastic Type: | Others |

| Use: | Others |

| Shaft Design: | Others |

| Brand Name: | Shunda |

| Power: | 13KW |

| Condition:: | New |

| Product Type:: | foam beads |

| Certification:: | CE |

| Place of Origin:: | Shandong China (Mainland) |

| quality guarantee period:: | 1 year |

| Plastic Type:: | EPS |

| Weight:: | 2800KG |

| Dimension(L*W*H):: | 3600x2000x3000mm |

| Voltage:: | 380V |

| engineer:: | two engineers for 10 days |

| Packing: | normal export packing |

| Delivery Date: | 30 days |

Product Description

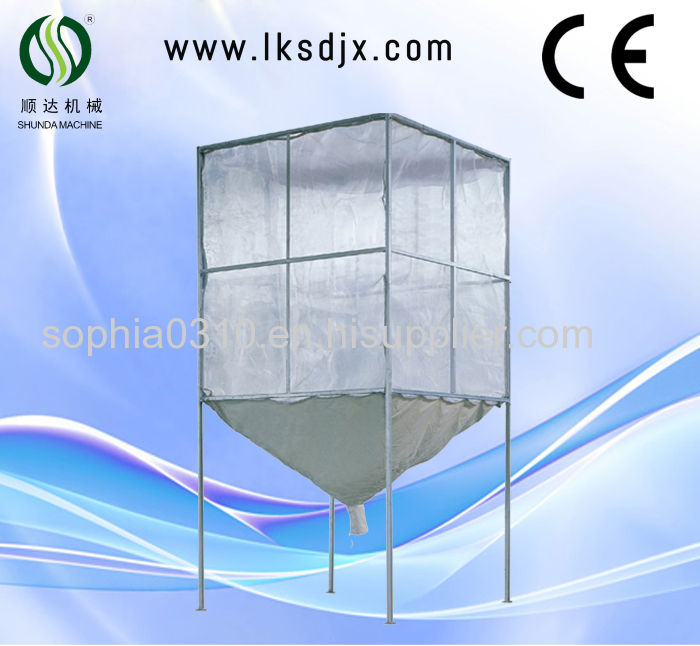

high quality eps expanded polystyrene machine

Specifications

We are the biggest and most competitive machinery manufacturer in China,offer eps machine more than 18 years,Contact now!

How to contact us?

Skype: xiaofei03102

Tel:86-18561054233

Product Description

Feature of our EPS pre-expander machine

This machine adopts PLC programmable controller and touching screen to carry out automatic production from feeding, temperature control, ration, pressurizing and feeding.

Top-grade sealing foaming with constant pressure, high thermal efficiency, save 50% steam or above than continuous foaming machine

Adopt high-precision imported pneumatic control valve so that temperature can be controlled at 1%, EPS grains are at same level with low water content.

Correct feeding method can assure even density

MAIN SPECIFICATIONS & PARAMETERS:

Expansion vessel: 800*1200(h)

Density range: 10~60kg/m3

Production efficiency: 60-100 Kg/h

Steam pressure: 0.4~0.8 Mpa

Compressed air pressure: 0.6~0.8 Mpa

Inlet of steam: 50mm

Inlet of compressed air: 50mm

Power: 1.5KW

Machine weight: approx. 2000kg

Overall dimension: 1800*1300*3000mm

A. EPS Batch Pre-expander:

MAIN FEATURES:

1. With PLC programmable controller and touch screen to control the whole working procedure automatically.

2. Use closed expansion chamber and pressure sensor control technology to realize stable foaming pressure.

3. Expansion chamber temperature is controlled by temperature sensor and valve position ensuring accurate temperature control.

4. Vibrating switch control material level to get accurate density, density tolerance less than ±2%.

5. Stainless steel fluidized bed drier keeps inside temperature around 70 ℃.

Why choose us?

1. Automatic product, High thermal efficiency, Low moisture content.

2. Little noise, Clamping force, High strength.

3. High production efficiency, High efficiency heat conduction.

4. High tensile strength, Long service life, High penetrating power.

5. Good adhesion, Use less gas, Rapid prototyping.

Transport process and Packaging products

We can solve the problem for you is

1.We have introduced South Korea and Taiwan technology with 34 years experience. Our machine quality is the best.

2.Our salesman will be 24 hours online for you to solve problems.

3.We can provide running machine video, layout, material introduction, cost analysis and any information you want.

3.After sales service: we will dispatch professional technicians to customer factory for machine installation and training.

We are specialized in manufacturing this production line with about 31 years experiences.

Our enterprise management concept is based on innovation, excellent quality and skilled workmanship. So we are enjoying a good reputation through over 100 countries and areas and have got customers' trust deeply. Moreover, our sales volume of foaming machinery is No. 1 compared with other Chinese suppliers.

We sincerely hope to cooperate with friends from home and abroad and help you succeed with our profession.

payment process

40% down payment by T/T

60% balance by T/T (Shipping after receipt of balance)

FAQ

1. Q: Are you a factory or trading company?

A: We are a factory.

2. Q: What certificate do you have?

A: We have ISO and CE certificate.

3. Q: How does your factory do regarding quality control?

A: We have a special QC department in charge of products' quality.

4. Q: How long is the warranty period?

A: All of our products have one year warranty.

5. Q: What's the main market of your company?

A: We have customers all over the world.

6. Q: How much production capacity of your company one year?

A: This depends on your needs.

7. Q: Where is your factory located? How can we visit there?

A: Our factory is located in Xufu Town, Longkou City, Shandong, China,We offer transportation service.