Auto screen changer for polymer melt filtration

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 100 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHW |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Belt Filter |

| Function: | Screening Filter |

| Brand Name: | DEAO |

| Product name: | screen changer/ melt filter |

| Attribute: | auxiliary equipment of plastic extrusion plant |

| Function: | polymer melt filtration |

| Application: | almost all polymers PP/PE//ABS/XPS/WPC |

| Material: | high quality alloy steel /38CrMoAl |

| Pressure resistant: | 350bar |

| Type: | different types to be match with extruders |

| Production Capacity: | 100 sets per month |

| Packing: | seaworthy packing |

| Delivery Date: | 40 days after receiving down payment |

Product Description

Auto screen changer for polymer melt filtration

Automatic belt screen changer

This kind of screen changer is made of two parts , the body of the screen changer(heating system and cooling system are included), the electric controlling cabinet(pressure sensor, temperature and pressre meter, thermocouple are included). The two parts form a whole set and both are indispensable .

Technical Data:

Type | Screen Belt W(mm)×L(m) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHW--70 | 76×10 | 2.5 | ≤40 | ≤200 |

DHW--100 | 107×10 | 3.5 | ≤40 | ≤500 |

DHW--120 | 130×10 | 5 | ≤35 | ≤800 |

DHW--150 | 160×10 | 7.5 | ≤35 | ≤1500 |

DHW--170 | 180×10 | 12.5 | ≤35 | ≤2000 |

DHW--200 | 210×10 | 14 | ≤35 | ≤3500 |

Performance of this kind of auto screen changer for polymer melt filtration

1, simple installment job , and after commissioning done, with out operator interference.

2. No fluctuation of material flow pressure, no product deformation, excellent quality stability.

3. No waste product or waste material, and little material consumption occur when change the screen.

4. Simple construction, reliable operation; Easy maintenance, lower running cost.

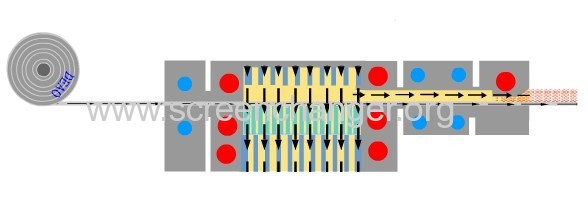

The structure of the body of the screen changer

1, red color:heater

2, blue color:cooling system

3, black color: the materal flow

When screen change

1, heating- screen move forward- cooling-the material in the screen exit get coolling and become solid

Auto screen changer for polymer melt filtration is widely used for

1. Extruders (Plastic Extruder, Cast Film, Blown Film Extruder, etc)

2. Plastic pipe production line

3. Pipe, PA, PET and PVC sheet extrusion lines

4. Pelletizer,Granulation, Non-woven, Plastic recycling and Monofilament machine

This kind of auto screen changer now is widely export to all over the wolrd.

we have customers from America, Turkey, Iran, Czech, Ireland, Mexico, poland and so on.

And they are satisfied with our high quality and incredible low price.And a lots of them become our repeat customers.