Plate type hydraulic continuous screen changer for polymer melt filtration

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 30 sets /month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Screen Changer, Double Piston Continuous Screen Changer, Double Piston Double Working Position Screen Changer, New Continuous Screen Changer, Automatic Belt Screen Changer For Extruders |

Product Detail

| Model No.: | DHBL |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Structure: | Hydraulic Filter |

| Function: | Purification Filter |

| Brand Name: | DEAO |

| Material: | high quality alloy steel(39CrMoAl) |

| Applied for: | plastic extrusion machine |

| Function: | filter the impurities in plastic polymer melt |

| Suitable materials: | almost all kinds of polymers |

| Type: | different type to be matched with different type of extruders |

| Pressure resistant: | 300bar/300kg/30Mpa |

| Temperature resistant: | 330℃ |

| Application fields: | pipe/sheet/cast film/blown film/recycling /chemical fiber/ and so on |

| Production Capacity: | 30 sets /month |

| Packing: | Seaworthy paking |

| Delivery Date: | 40 days after receiving the down payment |

Product Description

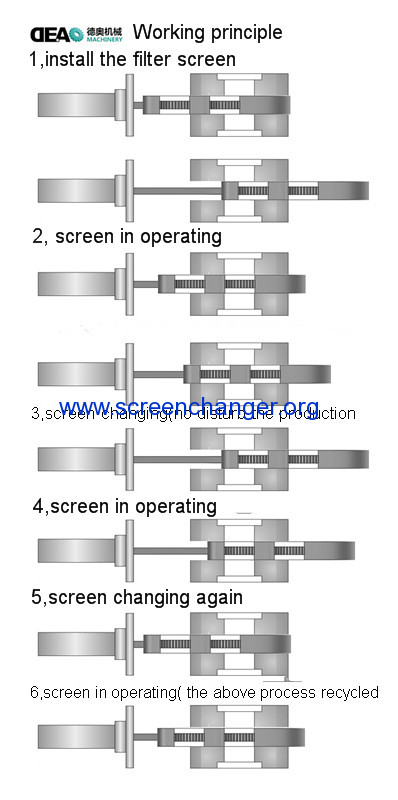

Plate type hydraulic continuous screen changer for polymer melt filtration

The new continuous screen changer is especially applicable to foaming plate products such as XPS, EPS, EPE and cast film. It ensures the screen changing without machine halt or production interrupt, which has been widely tested and verified in production practice.

Technical Data:

Type | Screen type (mm) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHBL-80 | 70×70 | 3 | ≤50 | ≤250 |

DHBL-100 | 100×90 | 5.6 | ≤50 | ≤450 |

DHBL-130 | 120×110 | 6.8 | ≤40 | ≤550 |

DHBL-150 | 140×130 | 8 | ≤40 | ≤900 |

DHBL-200 | 190×170 | 10 | ≤30 | ≤1500 |

Features included

1,No need to stop the working machine when changing the screen, no material explosion, noiseless, no material leakage, or production interrupt while working.

2,This Plate type hydraulic continuous screen changer for polrmer melt filtration

(self-owned patent ) is characterized by the convenience and safety to change the filtering screen with it. It is time-saving to install the filtering screen with the screen changer, and there is no need to manually disassemble the machine, adjust the para-position screen, or install the lock pact between different screens, thus the screen changing operation will be reduced by 90%.

Application fields:

1,Applicable to all kinds of plastic products.

2,Applicable to the production line of chemical fiber, rubber, collosol, adhesive, coating and finishing materials and other blending agent products, used for filtration of the material mixture.

Plate type hydraulic continuous screen changer for polymer melt filtration before delivery